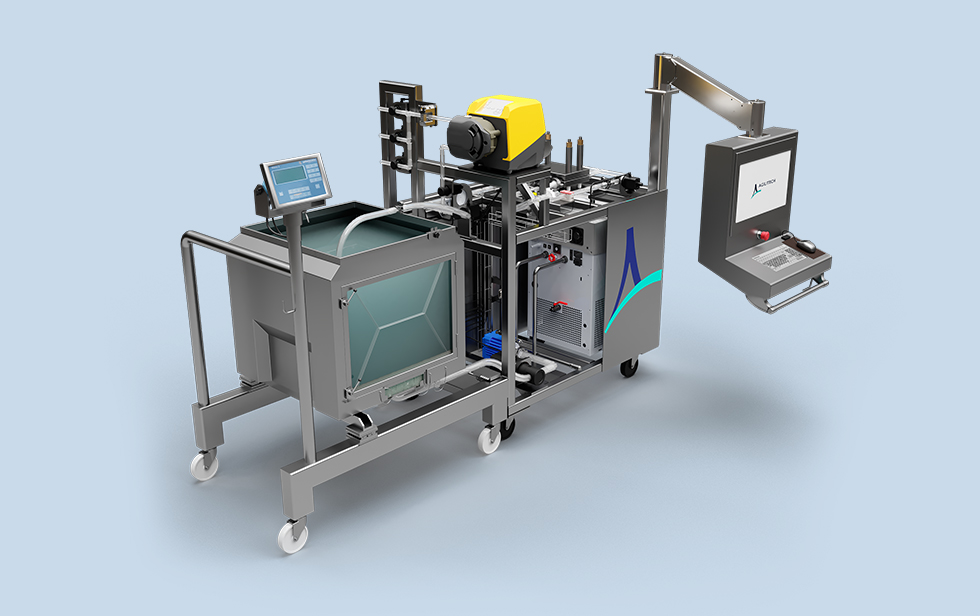

Agilitech now offers single-use Tangential Flow Filtration (TFF) systems for full-scale production with a choice of two models to meet different capacity needs, as well as customer-tailored skids.

“Like other Agilitech products, our new production-scale TFF systems provide customers distinct benefits when compared to competitive products. We call this ‘The Agilitech Advantage’.” said Phil Sanders, Biotech Chief Innovation Officer, Agilitech. “The new TFF systems are specifically designed to streamline bioprocesses, increase sample recovery, and reduce the cost of consumables.”

A magnetically levitated pump and cubical mixing bag with magnetic mixer limits shear on the product, maximizing yield. Optimal transmembrane pressure is maintained to optimize filter performance throughout the TFF process. Combined with an air modulated diaphragm pressure control valve, retentate pressure reaches set point quickly to achieve the desired TMP. “This eliminates pump pulsations and pinching control valves that lead to more erratic pressure control, another Agilitech Advantage.”, explained Sanders.

The system also maximizes product recovery in the recirculation bag. Users simply disconnect the tubing from the TFF skid and move the recirculation bag to the next step for further processing. The result is fewer consumables, reduced cost, and the elimination of project delays due to supply chain issues with consumables.

The Single-use TFF System is offered in two models. The T750 has a 250 L tank capacity, and the T1000 has a tank size of up to 1000 L. Both models have an open system design to provide complete flexibility for our expert engineers to adapt the TFF skid to meet specific user requirements.

The single-use TFF systems are available through Agilitech’s team of authorized manufacturer’s representatives.