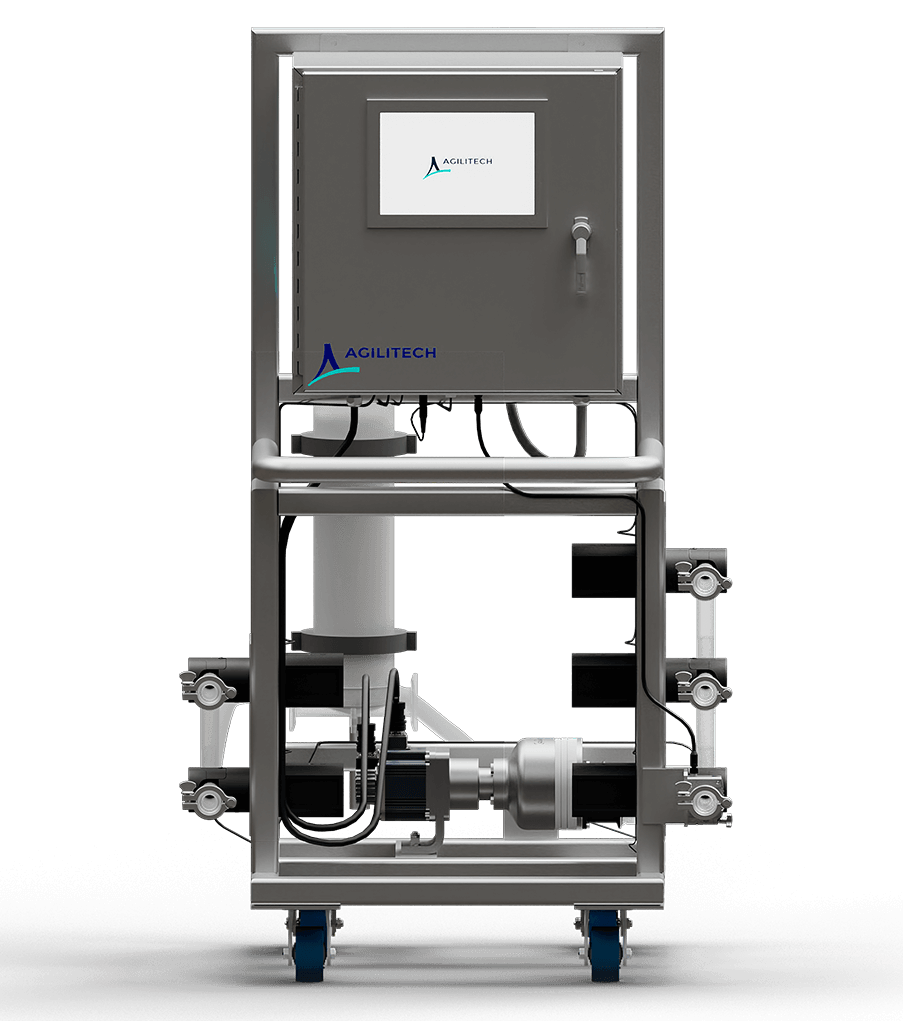

Single-Use Sterile Filtration System

Next-level flexibility for your sterile filtration needs.

One skid accommodates multiple sterile filter sizes, increasing productivity while reducing costs

Brand-agnostic design permits the use of best-in-class components for every part of the system

Integrate with your preferred sterile filter brand to ensure sterility and maximize product recovery

Dynamic flow control automatically decreases flow rate should filters foul and pressure increase, ensuring safe working conditions

Manual control or integrates seamlessly with state-of-the-art automation platforms (DeltaV®, Rockwell Automation®, or other)

Volume totalizer monitors liquid volume pumped through the system

Multiple inlets (for product, buffer, water) and outlets (for product collection or waste)

Want to learn more about the Agilitech single-use sterile filtration system?

A single-use sterile filtration system that redefines flexibility

Single-use filtration systems are routinely used in bioprocess to increase production efficiency and to ensure product safety. The Agilitech sterile filtration system is a highly adaptable single-use platform for your sterile filtration applications. The system offers flexibility that is next-level; for example, it can be tailored to accommodate your preferred sterile filter brand, creating a system that meets your specific needs.

Our unique collaborative front-end planning and product design process starts with you. We invest the time up front to understand your current needs and future development goals before adapting our standard sterile filtration system to fit your purpose. Agilitech single-use sterile filtration systems are designed to be brand agnostic. We can accommodate your specific brand preferences, while best-in-class components are used for every aspect of the system to optimize performance.

Adaptability that’s revolutionary

System can be adapted for larger or smaller sized sterile filters, depending on your needs now and in the future.

The unique design of the Agilitech sterile filtration system allows for multiple filter sizes to be used with the same skid. This enables your process to evolve as your needs change, keeping costs down and increasing productivity.

Agilitech understands that in a fast-moving industry that is constantly evolving, our customers have specific requirements that must be met quickly. The design of our sterile filtration system to consider multiple filter options is truly next-level.

Flexible control

ISA-88 compliant design enables both manual and automated operation.

The manual control panel is intuitive and easy to use. Our engineers have decades of experience and have listened to customer needs, identifying the data and functions that operators need to access most often; our user interface brings these functions and data to the top layer of the screen, eliminating endless clicking or searching for critical information.

The sterile filtration system can also be delivered with your preferred automation and control platform—whether that’s DeltaV®, Rockwell Automation®, or another leading platform. Our product design and engineering team has deep knowledge and experience with a wide range of automation and control platforms to ensure seamless integration with your existing systems. Regardless of the platform you choose, the user experience is the same due to the ISA-88 batch-compliant structure.

A choice of models

A range of models is offered to accommodate different tubing sizes and flow rates for lab to production scale bioprocesses. All models provide the same basic functionality and performance.

F500

Tubing ID:

0.50 in

Flow Rates:

0.167–15 LPM

Flow Sensor

Performance:

0–20 LPM (± 3%)

F750

Tubing ID:

0.75 in

Flow Rates:

0.167–20 LPM

Flow Sensor

Performance:

0–50 LPM (± 3%)

F1000

Tubing ID:

1.0 in

Flow Rates:

0.8-90 LPM

Flow Sensor

Performance:

0–100 LPM (± 3%)

Technical Specifications

| Attribute | Specification |

|---|---|

| Pressure | 0-60 psi/4 bar |

| Operating Temperature Range | 2–50°C |

| Humidity (non-condensing) | 10–90% |

| Utility Required, Skid Power* | 110-120 VAC |

| Wetted Materials | USP <88> Class VI and animal free |

| Inlets | 3 |

| Outlets | 2 |

| Flow Accuracy | ±3% |

| Pressure Sensor Performance | 0–6 psi (± 2%) 6–30 psi (± 3%) 30–60 psi (± 5%) |

*Compressed air (oil free) @ 80 psi/5.5 bar

Specifications represent standard Agilitech models and may change when customized for specific customer applications. Specifications subject to change without notice.

Quality manufacturing backed by world-class service and support

All Agilitech single-use systems are manufactured to the highest standards and delivered with the documentation you need:

- Standard Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) documentation provided upon delivery; we can also use your specific documentation, if preferred

- Installation Qualification (IQ) and Operational Qualification (OQ) testing and documentation available for use in cGMP production

All Agilitech single-use systems are also delivered with a recommended preventative maintenance plan and spare parts list. We also provide maintenance service to ensure your system operates at peak performance.

Featured Content

DOWNSTREAM COLUMN BLOG: Flexible Single-Use Technology that Adapts to an Evolving Industry

One thing constant in biopharmaceutical manufacturing is change. There is an ever-present need to adapt to new therapeutic modalities, more cost-effective approaches, higher product demands, and even a worldwide pandemic.

PODCAST: Addressing the increasing demand for single-use technologies and supply chain shortages with future-proof systems

We’re pleased to share this new podcast recently published by Downstream Column; a conversation about single-use technologies.

PODCAST: Single-Use Mixers – Ensuring the Customization, Scalability and Supply Required for Success

In this podcast, Brandy Sargent, Editor at Cell Culture Dish, talks with Phil Sanders (Chief Innovation Officer) and Dennis Hodgson (Director, Biotech) from Agilitech about the benefits of single-use mixers, dealing with supply chain concerns, ensuring scalability, and tailoring a mixer to meet specific process needs.

Want to learn more about the Agilitech single-use sterile filtration system?

Please complete this form and an Agilitech specialist will be in touch.