Stir Vessel Bioreactor System

Adapts to Your Changing Needs

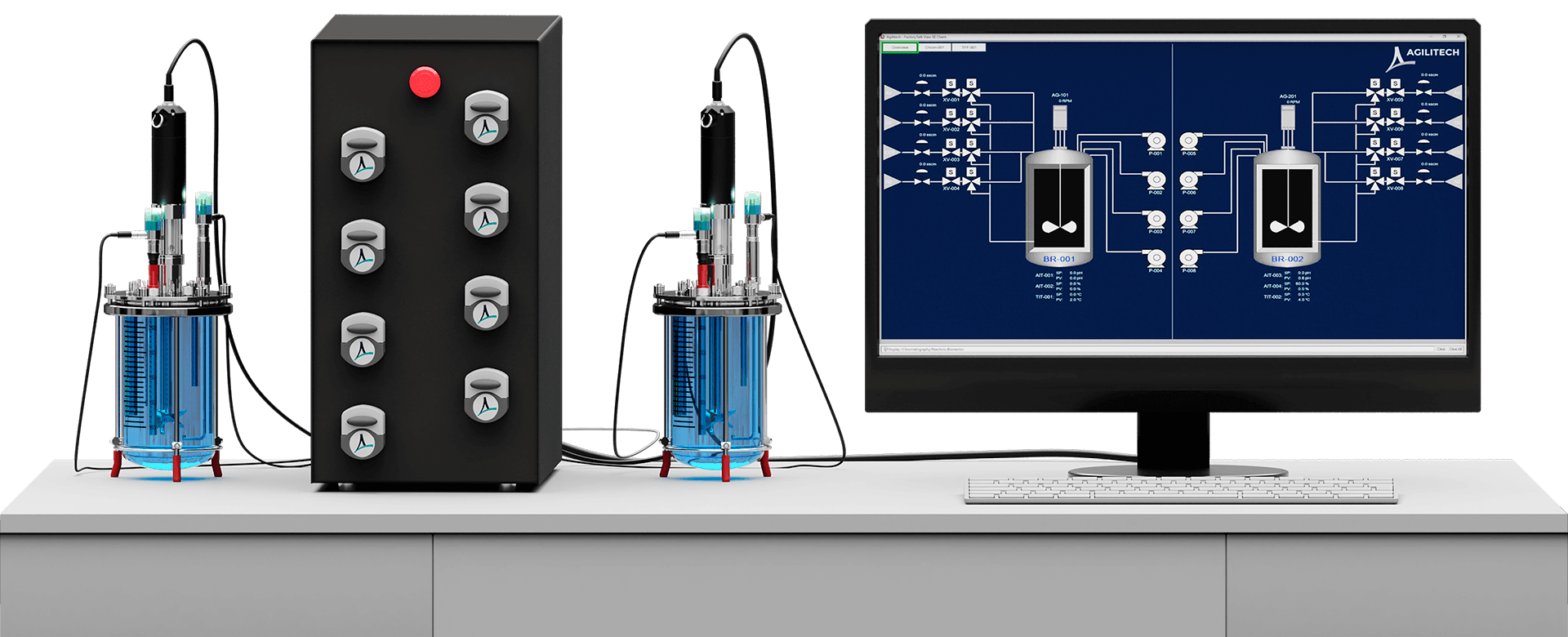

Flexible and Compact Stir Vessel Bioreactor System

The Agilitech benchtop bioreactor system accommodates two stir vessels in one of the smallest footprints available. With a brand-agnostic design, you have the option to choose your own vessel configuration, preferred sensors, as well as the automation and control platform.

Choose from jacketed or single wall vessels in 3 L, 5 L, 7 L, 15 L, or 20 L sizes and an extensive array of standard and engineered options for both cell culture and microbial applications.

The system is delivered complete with your preferred sensors, whether Mettler Toledo, Broadley James, Hamilton, or other. Designed with state-of-the-art open architecture, the control system accommodates additional scales for vessel weight and additional sensors for perfusion applications. And it can be delivered with your preferred automation and control system.

Simultaneous control of two vessels

Ideal for microbial and cell culture vessel configurations

Brand-agnostic design

State-of-the-art automation based on S88 standards

Delivered with your preferred control system: DeltaV, Rockwell Automation, or other

Flexible operation: manual to fully automated batch operations

Up to 8 pumps for fluid management

Up to 8 mass flow controls for gas management

Durable stainless steel housing

Easy access to agitator motor adapters

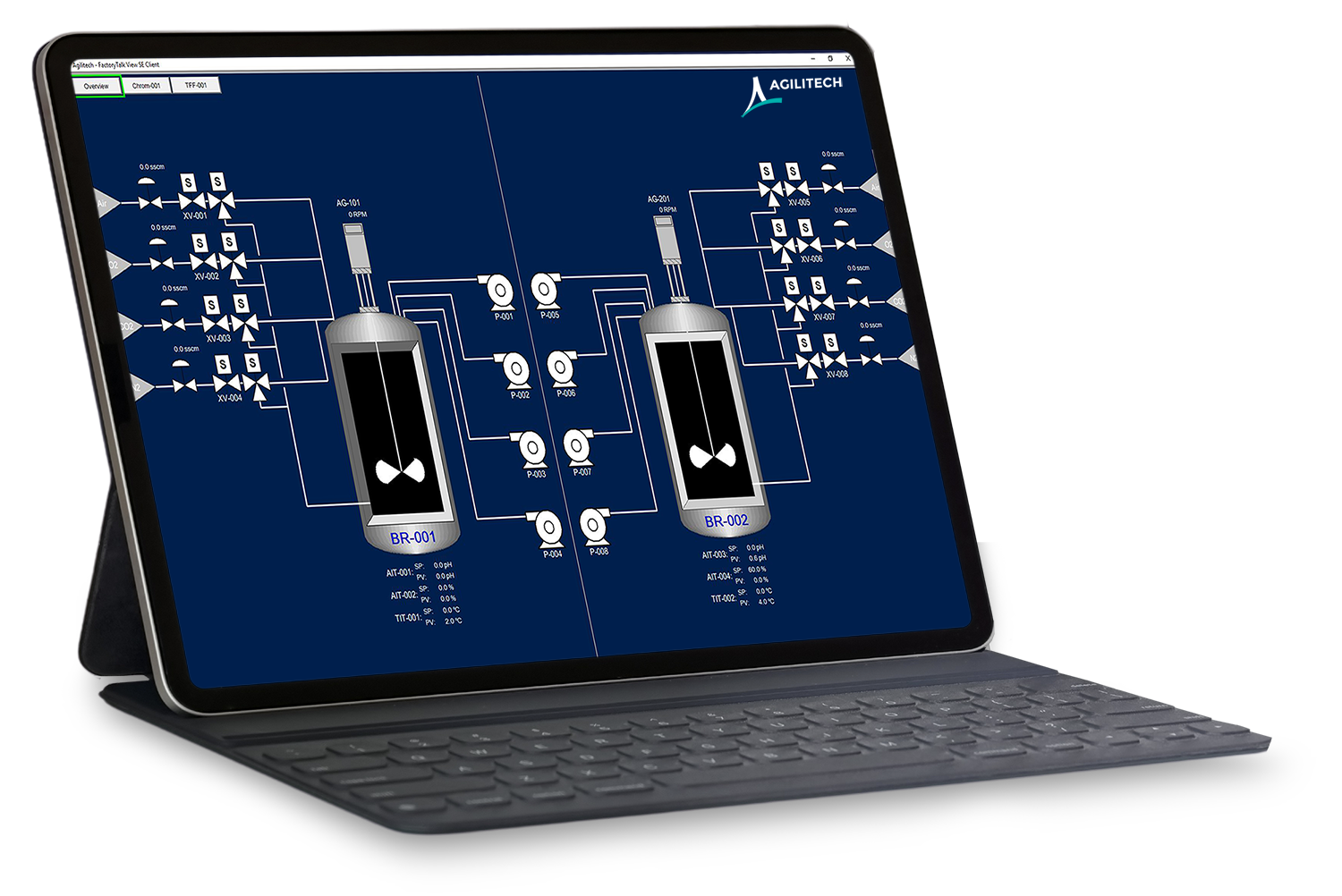

State-of-the-art automation and control

The bioreactor system controls are based on S88 standards to support manual operation to full batch control. It can be delivered with DeltaV, Rockwell Automation, Inductive Automation Ignition, Wonderware, or other control system – the choice is yours.

The controller interface is also incredibly easy to use and offers you added convenience by bringing the most commonly used functions and data to the top layer of the screen, which eliminates endless clicking and digging to access data. The ISA-88 batch-compliant structure ensures the same ease of use and feel of the system regardless of the platform.

Technical Specifications

| Attribute | Controller |

| Dimensions | 24.8 x 24 x 12.6 in (H x D xW) |

| Operating Temp. | 5 – 40°C |

| Relative Humidity | 5 – 95% Non-Condensing |

| Agitation | Variable Speed Servo Motor with Agitator Blade Adapters |

| pH / DO | Mettler Toledo, Broadley James, Hamilton, Endress+Hauser |

| Temp | 100 Ohm RTD in thermowell |

| Liquid Control | 8x Cole Parmer Miniflex Variable (0-330 mL/min depending on tubing dimensions) |

| Temperature Control | Heating Blanket; 3-way solenoid valve for chilled liquid, if applicable |

| Gas Control | 8x MFC w/direction control for overlay or sparge |

| Scale/Balance | Not in base solution, but can add |

| Antifoam | Not in base solution, but can add |

| Attribute | Stir Vessel |

| Sizes | 3, 5, 7, 15, 20 L |

| Applications | Cell culture and microbial applications |

| Vessel Type | Single wall or jacketed with tripod stand |

| Sensors | pH, DO, temperature |

| Drive System | Direct drive and magnetically coupled agitation assemblies |

| Head plate | 316 L stainless steel electropolished |

| Heating | 110 VAC blanket heats to 3 watts per square inch |

DeltaV is a registered trademark of Emerson; Rockwell Automation is a registered trademark of Rockwell Automation, Inc; Wonderware is a registered trademark of Wonderware Corp; Broadley-James is a registered trademark of Broadley-James Corporation; Cole-Parmer is a registered trademark of Cole Parmer Instrument Comany; Endress+Hauser is a trademark of Endress+Hauser Group Services AG; Hamilton is a registered trademark of Hamilton Company.

Quality manufacturing backed by world-class service and support

All Agilitech products are manufactured to the highest standards and delivered with the documentation you need:

- Standard Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) documentation provided upon delivery; we can also use your specific documentation, if preferred

- Installation Qualification (IQ) and Operational Qualification (OQ) testing and documentation available for use in cGMP production

- Performance Qualification (PQ) testing available, if needed

- Supplemental documentation provided, as needed, e.g., Qualification Project Plan (QPP), Criticality Assessment and Risk Assessment can also be provided

Agilitech products are also delivered with a recommended preventative maintenance plan and spare parts list. We also provide preventative maintenance service to ensure sensors and all other components continue to function at peak performance.

You have a vision for your bioprocess.

We can help you get there.