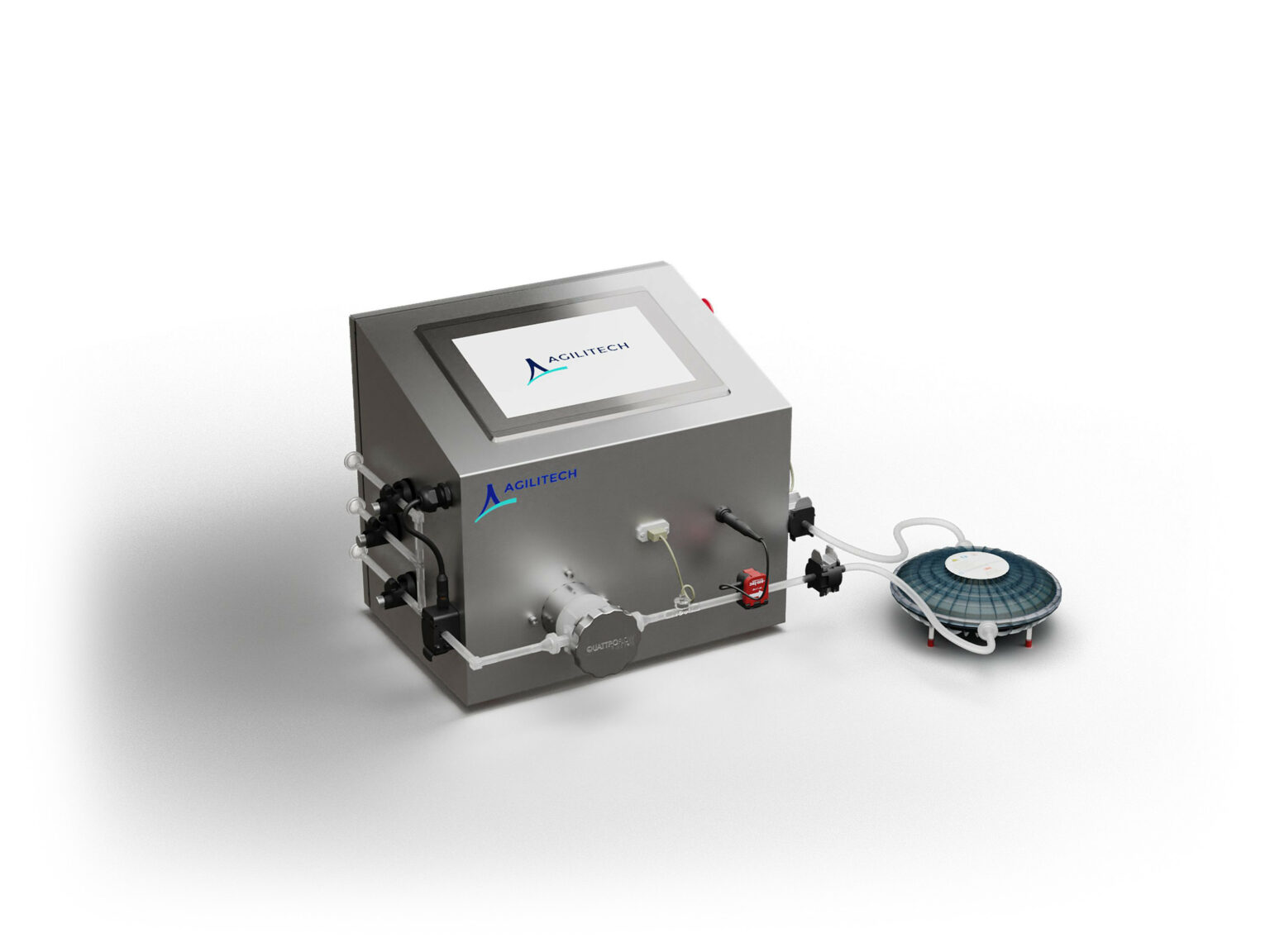

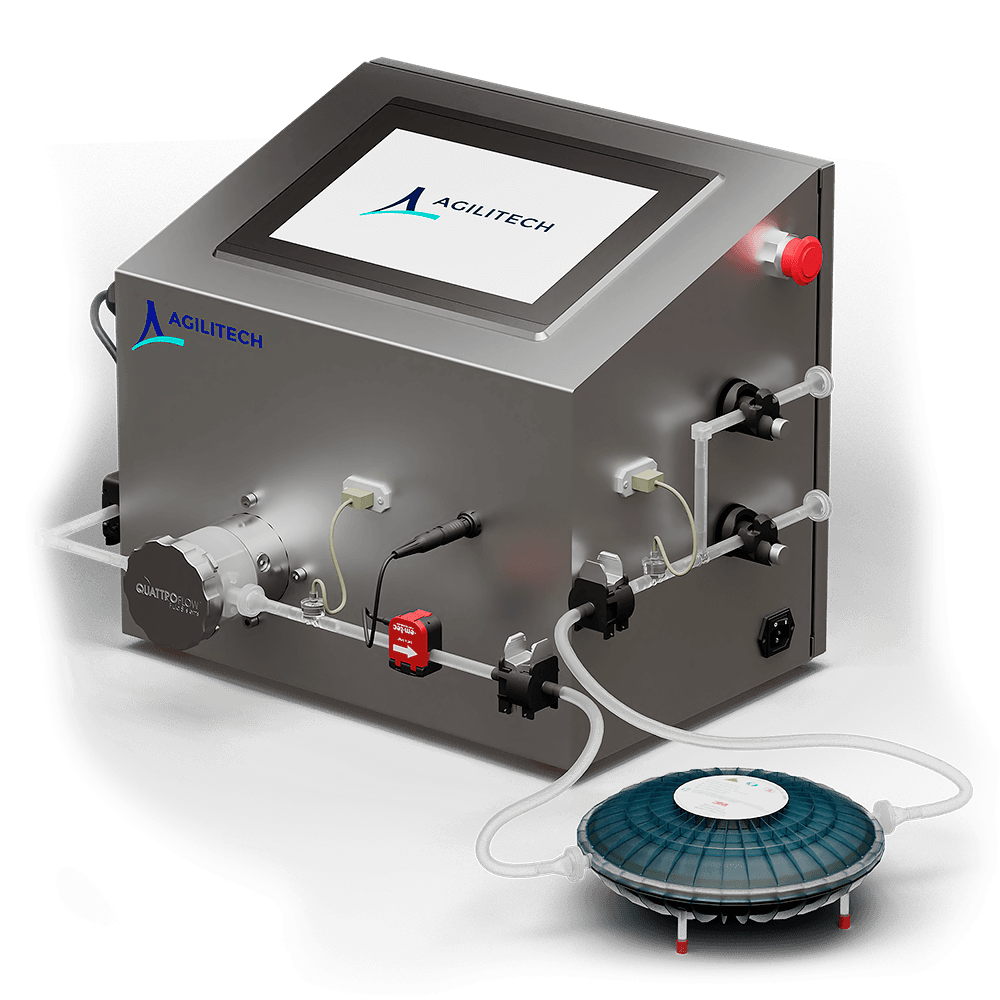

Single-Use Multipurpose Filtration System Up To 3 LPM

Flexibility redefined

Universal filtration system for all your needs: virus filtration, depth filtration, and sterile filtration

Brand-agnostic design enables use of best-in-class components for every part of the system

Adapts to virtually any external filtration system

Dynamic flow control automatically decreases flow rate should filters foul and pressure increase, providing safe working conditions

Seamless integration with state-of-the-art automation platforms (DeltaV®, Rockwell Automation®, or other)

Volume totalizer monitors liquid volume pumped through the system

Multiple inlets (for product, buffer, water) and outlets (for product collection or waste)

Versatile single-use filtration system tailored to your exact needs

The Agilitech multipurpose bioprocess filtration system is a highly versatile single-use platform that can be tailored to your unique needs and adapted to virtually any external filtration system. The system can be used to perform sterile filtration, depth filtration, or virus filtration.

With Agilitech single-use technologies, you are a co-designer of your solution. We employ a front-end planning process, taking the time to understand your current and future needs before adapting our standard filtration system to fit your specific requirements. The brand-agnostic design provides complete flexibility with filters and other components to optimize the system for your unique process.

Flexible brand-agnostic design

The multipurpose filtration system can accommodate your specific brand preferences for filters and other components. It can also be adapted to any modern control system, including DeltaV®, Rockwell Automation®, or another platform, allowing your engineering team to make modifications as needed.

The system provides all of the inherent benefits of single-use technologies: fully sterilized single-use tubing sets, as well as integrated sensors and sterile-to-sterile connections for inlets and outlets minimize contamination risks. Agilitech systems use only the highest quality components (USP <88> Class VI certified single-piece tubing sets) to ensure sterility throughout use.

Choose your preferred automation and control system

The system can be delivered with your preferred automation and control platform. Our engineering experts have years of experience with DeltaV®, Rockwell Automation®, and other leading platforms; we can integrate the system to meet your requirements. Regardless of the platform you choose, the user experience is the same due to the ISA-88 batch-compliant structure that is used to create the building blocks of the automation.

Easy-to-use, intuitive control panel

The user friendly control panel is easy to use. Our engineers have listened to customer needs and have identified the functions and data that operators need to access most often; the user interface brings these functions and data to the top layer of the screen to eliminate endless clicking or digging for critical information.

Technical Specifications

| Attribute | F125 | F250 |

|---|---|---|

| Tubing ID: | 0.125 in | 0.25 in |

| Flow Rates: | 1-500 mL/min | 16-3000 mL/min |

| Flow Sensor Performance: | 0–4 LPM (± 3%) | 0–8 LPM (± 3%) |

| Pressure | 0-60 psi/4 bar | 0-60 psi/4 bar |

| Operating Temperature Range | 2–50°C | 2–50°C |

| Humidity (non-condensing) | 10–90% | 10–90% |

| Utility Required, Skid Power* | 110-120 VAC | 110-120 VAC |

| Wetted Materials | USP <88> Class VI and animal free | USP <88> Class VI and animal free |

| Inlets | 3 | 3 |

| Outlets | 2 | 2 |

| Flow Accuracy | ±3% | ±3% |

| Pressure Sensor Performance | 0–6 psi (± 2%) 6–30 psi (± 3%) 30–60 psi (± 5%) |

0–6 psi (± 2%) 6–30 psi (± 3%) 30–60 psi (± 5%) |

*Compressed air (oil free) @ 80 psi/5.5 bar

Specifications represent standard Agilitech models and may change when customized for specific customer applications. Specifications subject to change without notice.

Quality manufacturing backed by world-class service and support

All Agilitech single-use systems are manufactured to the highest standards and delivered with the documentation you need:

- Standard Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) documentation provided upon delivery; we can also use your specific documentation, if preferred

- Installation Qualification (IQ) and Operational Qualification (OQ) testing and documentation available for use in cGMP production

All Agilitech single-use systems are also delivered with a recommended preventative maintenance plan and spare parts list. We also provide maintenance service to ensure your system operates at peak performance.

You have a vision for your process.

We can help you get there.