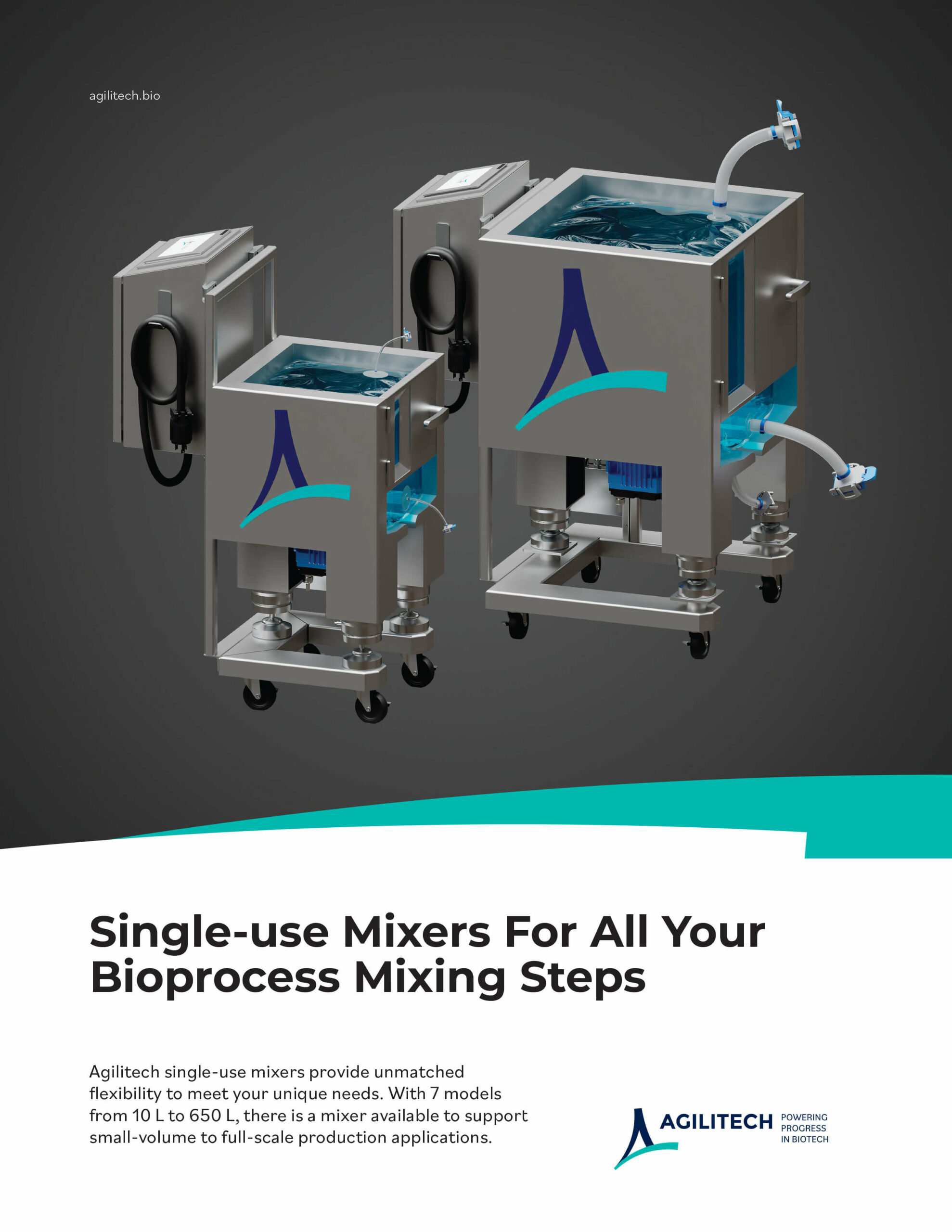

Single-Use Mixers

10 L to 650 L models for all of your bioprocess mixing steps

Uniquely flexible single-use mixers for all your bioprocessing needs

Agilitech single-use mixers are available in 7 sizes from 10 L to 650 L for handling small-volume highly concentrated samples up to full-scale production. As with all Agilitech single-use technologies, our customers are co-designers of their single-use solution. We invest the time up front to understand your current and future needs before adapting our standard mixer design to fit your unique bioprocess.

7 models available: 10 L, 25 L, 50 L, 100 L 250 L, 400 L, 650 L

Unique built-in motor offers flexible control and easy handling

Fully cutomizable single-use mixer bags

Jacketed or non-jacketed varieties

Low-shear mixing using Levitronix® MagLev Mixers

Control manually or easily integrate with your automation and control platform

Built-in load cells for monitoring the weight of solution

Resistance temperature detector (RTD) provides increased stability, precision, and repeatability of temperature measurements

Durable stainless steel construction with heavy-duty casters for easy transport

Fully customizable single-use mixer bags

The mixer is completly single use with fully sterilized single-use bags and components to minimize the risk of contamination. Sterile-to-sterile connections for inlets and outlets also reduce contamination risks. We use only the highest quality components; USP <88> Class VI certified single-piece tubing sets to ensure sterility throughout use.

Single-use mixer bags can be customized with additional ports, as needed, to meet your specific application requirements. This includes inlets, outlets, and sample ports.

Analytical measurements such as pH, conductivity, and dissolved oxygen can also be added.

Built-in motor with flexible control

Agilitech single-use mixers feature a built-in motor with manual control, as well as fast and easy integration with your preferred automation and control system via Ethernet I/P Connect.

Manual Control

The local display enables manual control of the motor and provides convenient display of weight, temperature and any other connected analytical devices. The intuitive control panel is easy to use. Our engineers have listened to customer needs and have identified the functions and data that operators need to access most often; the user interface brings these functions and data to the top layer of the screen to eliminate endless clicking or digging for critical information.

Integrated Control

For automated control, choose the automation and control platform that fits your needs best. Our engineering experts have years of experience with DeltaV®, Rockwell Automation®, and other leading platforms; we can integrate the system to meet your requirements. Regardless of the platform you choose, the user experience is the same due to the ISA-88 batch-compliant structure that is used to create the building blocks of the automation.

When integrated directly into your control system, mixer operation can be conveniently controlled as part of your TFF system, depth filtration system, virus filtration system, and/or other connected devices. Integration with your control system also enables your engineering team to make modifications on their own whenever you need them.

Technical Specifications

Technical Specifications, All Models

| Attribute | |

|---|---|

| Jacket Maximum Working Pressure | 15 PSI |

| Tank and Frame Material | 304L SS, #4 Finish (29-40 RA) |

| Legs | Threaded stem leveling caster; swiveling; clean room compatible |

| Agitator Motor | Levitronix® |

| Maximum Working Temperature | (°C) 50 |

| Control System | Rockwell MicroLogix® with 7-inch PanelView® 800 |

| Communications | Ethernet IP/Modbus TCP |

| Load Cells | Minebea Intec PR 6211 / PR 6012; ± 1% |

| RTD Temperature Sensor | Included; ± 0.2°C |

| Input Power | 100-240 VAC, 50/60 Hz (See model specifications for amperage) |

| Options | |

| pH Sensors | Hamilton SU or Mettler Toledo SU pH sensors for bags Traditional probes with insertion sheath |

| Conductivity Sensor | Hamilton SU conductivity sensors for bags Traditional probe with insertion sheath |

| Temperature Control | Thermo Fisher TCU |

Technical Specifications

| Model | M10 | M25 | M50 | M100 | M250 | M400 | M650 |

|---|---|---|---|---|---|---|---|

| Bag Size | 10 L | 25 L | 50 L | 100 L | 250 L | 400 L | 650 L |

| Vessel Width (in) | 14 | 17 | 20 | 24 | 31 | 36 | 42 |

| Vessel Depth (in) | 26 | 29 | 32 | 36 | 43 | 48 | 54 |

| Vessel Height (in) | 42 | 42 | 42 | 42 | 50 | 50 | 50 |

| Bag Edge Dimensions (in) | 10 | 13 | 16 | 20 | 27 | 32 | 37 |

| Minimum Mixing Volume (L) | 1.1 | 4 | 6.3 | 10 | 25.9 | 34.6 | 47.9 |

| Minimum Sampling Volume (L) | 3.4 | 6.3 | 10 | 15.9 | 29.2 | 40 | 55.3 |

| Maximum Working Volume (L) | 12 | 30 | 60 | 120 | 300 | 480 | 780 |

| Agitator Motor Model | i30 | i600 | i600 | i600 | i2048 | i2048 | i2048 |

| Max Rotation Speed (rpm) | 4600 | 1650 | 1650 | 1650 | 1100 | 1100 | 1100 |

| Amperage (A) | 3 | 8 | 8 | 8 | 15 | 15 | 15 |

| Motor Voltage (VDC) | 24 | 24 | 24 | 24 | 48 | 48 | 48 |

| Optional | |||||||

| Maximum number of side ports | 1 | 2 | 3 | 3+ | 3+ | 3+ | 3+ |

| Inlet/Outlet Tubing ID | 1M 1/4 in. | 1M 1/4 in. | 1M 1/2 in. | 1M 1/2 in. | 1M 1/2 in. | 1M 1 in. | 1M 1 in. |

Literature and Related Content

Floorstanding Stainless Mixers

7 Models from 650 L down to 10 L (939 KB)

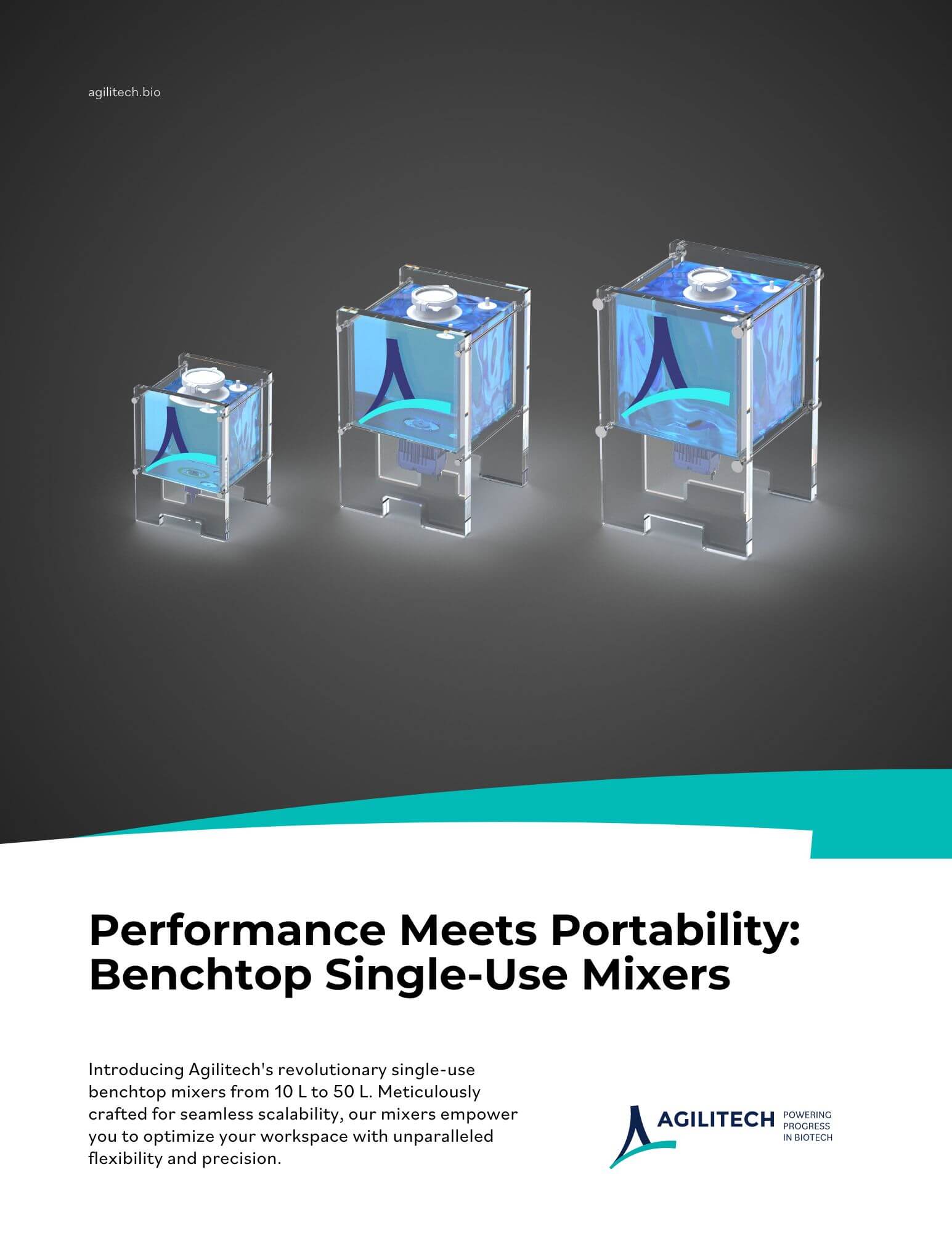

Portable Benchtop Mixers

Performance Meets Portability (2.8 MB)

PODCAST: Addressing the increasing demand for single-use technologies and supply chain shortages with future-proof systems

We’re pleased to share this new podcast recently published by Downstream Column; a conversation about single-use technologies.

PODCAST: Single-Use Mixers – Ensuring the Customization, Scalability and Supply Required for Success

In this podcast, Brandy Sargent, Editor at Cell Culture Dish, talks with Phil Sanders (Chief Innovation Officer) and Dennis Hodgson (Director, Biotech) from Agilitech about the benefits of single-use mixers, dealing with supply chain concerns, ensuring scalability, and tailoring a mixer to meet specific process needs.

Quality manufacturing backed by full-service support

All Agilitech products are manufactured to the highest standards and delivered with the documentation you need:

- Standard Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) documentation provided upon delivery; we can also use your specific documentation, if preferred

- Installation Qualification (IQ) and Operational Qualification (OQ) testing and documentation available for use in cGMP production

- Performance Qualification (PQ) testing available, if needed

- Supplemental documentation provided, as needed, e.g., Qualification Project Plan (QPP), Criticality Assessment and Risk Assessment can also be provided

Agilitech products are also delivered with a recommended preventative maintenance plan and spare parts list. We also provide preventative maintenance service to ensure sensors and all other components continue to function at peak performance.

Want to learn more about Agilitech Single-Use Mixers?

Please complete this form and an Agilitech specialist will be in touch.