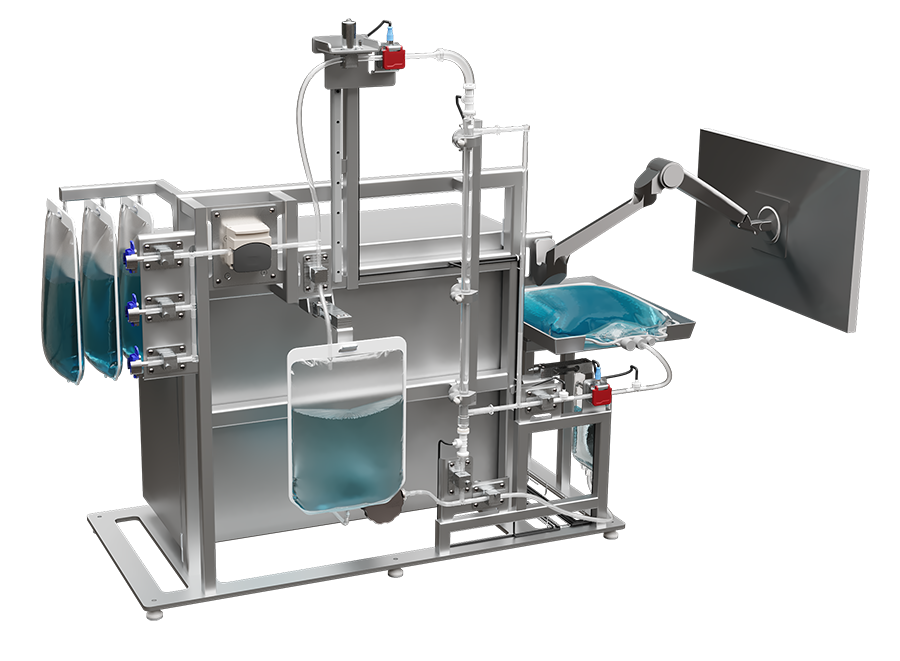

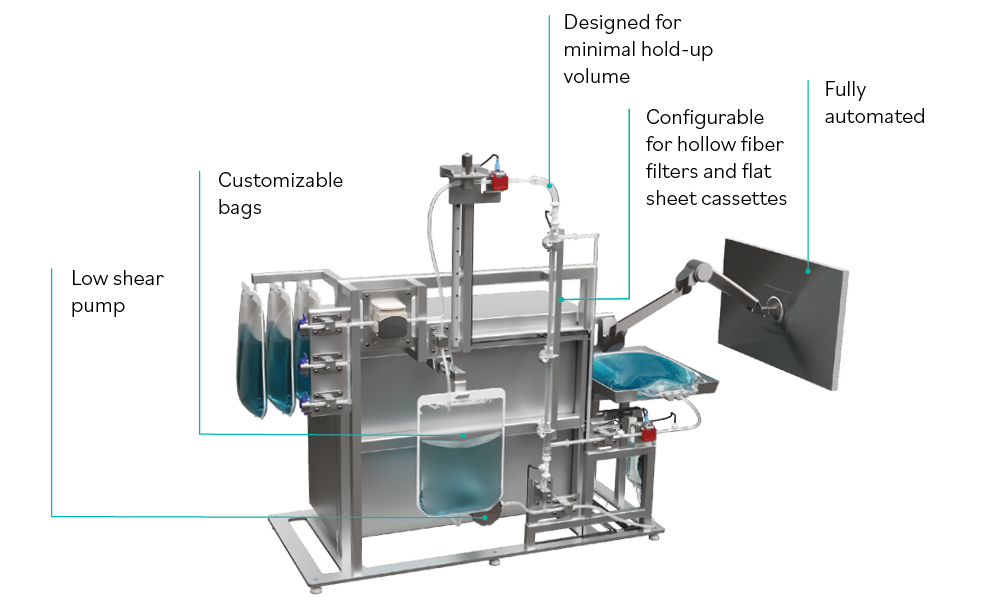

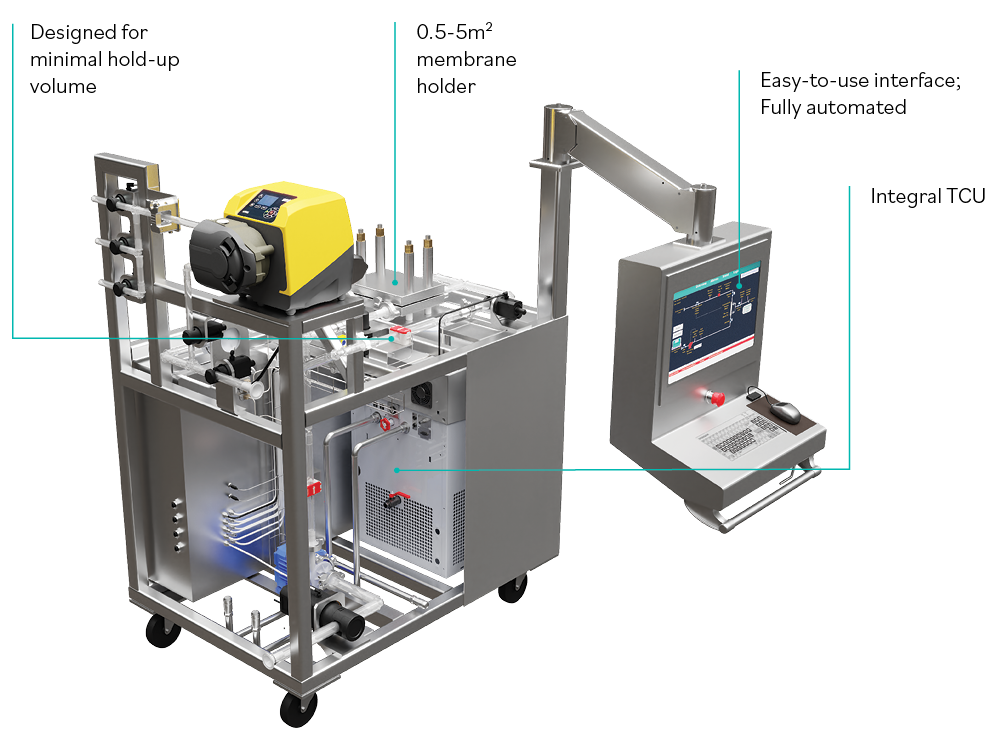

Next Generation Single-use TFF Systems

Flexible and scalable tangential flow filtration systems tailored to meet your unique bioprocess needs

Can be configured for both hollow fiber filters and flat sheet cassettes

Ultra-low hold-up volume minimizes product loss and ensures maximum yield

Low shear pump minimizes shear during recirculation

ISA-88 batch-compliant design for manual to fully automated control, 21 CFR Part 11 compliant

Seamless integration with your preferred platform—whether that’s DeltaV, Rockwell Automation, Inductive Automation Ignition Software, Wonderware, or other platform

Customizable gamma-irradiated flow path assemblies with integrated sensors and sterile-to-sterile connections for inlets/outlets minimize risk of contamination

Easy-to-use , intuitive control panel

From benchtop to large scale: Agilitech’s next-generation TFF systems provide unparalleled flexibility with optimized performance.

At Agilitech, we understand that filtration needs can change over time. That’s why we offer adaptable solutions that meet your current requirements and can evolve with your process. Our team of experts will work closely with you to understand your specific needs and tailor our standard system design to fit them precisely. Our scalable solutions range from compact benchtop models to production-scale with flow rates up to 100 LPM. Our new generation TFF systems are also highly adaptable, accommodating both hollow fiber filters and flat sheet cassettes, as well as different filter sizes in the same skid. As with all Agilitech single-use technologies, brand-agnostic product designs allow us to integrate best-in-class components and your preferred automation and control platform. Controls are based on an ISA 88 batch-compliant design, ensuring compliance with standards like 21 CFR Part 11.

Benchtop Models

Floorstanding Models

State-of-the-art automation and control—your way

We can deliver the TFF skid with your preferred automation and control system whether that’s DeltaV, Rockwell Automation, Inductive Automation Ignition Software, Wonderware, or other platform. Our seasoned engineers have decades of experience across a wide range of platforms. Regardless of the platform you choose, the user experience is the same due to the ISA-88 batch-compliant structure that is used to create the building blocks of the automation.

Easy-to-use, intuitive control panel

Our automation engineers have listened to end users and applied years of bioprocess experience to optimize the user interface of the TFF system control panel. We have identified the functions and data that operators need to access most often, and the user interface brings these functions and data to the top layer of the screen—no more endless clicking or digging to access data.

Quality consumables customized for your unique process

The components integrated with Agilitech single-use systems, such as flow path assemblies and 2D/3D bags, are produced by Entegris. With more than 50 years of proven materials science experience behind them, Entegris has developed deep technical expertise to deliver world-class production and exceptional consistency. Entegris flow path assemblies are manufactured to the highest standards and are delivered preassembled, sterilized, and use only optimized components to ensure consistent quality and operational excellence.

- Customized flow path assemblies with integrated sensors and sterile-to-sterile connections—sized to specific batches; accommodate different filters and instrumentation

- 2D Bags—scalable based on batch sizes with customizable inlet and outlet ports

- 3D Bags— scalable to any size up to 2500L with customizable inlet, outlet, sampling, and instrumentation ports

Technical Specifications

Benchtop models - flow ranges up to 7.7 LPM

| Attribute | T125 | T250 |

|---|---|---|

| General Skid Specifications | ||

| Tubing Internal Diameter | Feed and Retentate: 0.125 in Permeate: 0.125 in Inlets: 0.125 in |

Feed and Retentate: 0.25 in Permeate: 0.25 in Inlets: 0.25 in |

| Feed Flow Rate | 1-500 mL/min | 0.5-7.7 LPM |

| Tank Size | Up to 10L | Up to 50L |

| Pressure rating | 60 psi/4 bar | 60 psi/4 bar |

| Temperature Range | 2–50°C | 2-50°C |

| Humidity (non-condensing) | 10-90% | 10-90% |

| Utility Requirements* | 100-120 VAC | 100-120 VAC |

| Wetted Materials | USP <88> Class VI and animal free | USP <88> Class VI and animal free |

| Membrane Holder Capacity | 0.01 m2 to 0.04 m2 | 0.01m2 to 2.0 m2 |

| Feed and Filtrate Flow Measurement | Clamp on ultrasonic flow sensor (±3%) | Clamp on ultrasonic flow sensor (±3%) |

| Inlets | 1 product 2 buffers |

1 product 2 buffers |

| Outlet Ports | 1 Filtrate | 1 Filtrate |

| Minimum Working Volume Agitator Top Agitator Bottom Bag Sensors/Sampling |

Depends on mixer selected | Depends on mixer selected |

| Hold-Up Volume (excludes filtration device) | 25 mL | 50 mL |

| Dims (W x D x H)** | 635 x 559 x 635 mm | 635 x 559 x 635 mm |

| Sensor Performance | ||

| Pressure | 0-6 psi (± 2%) 6-30 psi (± 3%) 30-60 psi (± 5%) |

0-6 psi (± 2%) 6-30 psi (± 3%) 30-60 psi (± 5%) |

| Filtrate Conductivity | 0-100 mS/cm (± 3%) | 0-100 mS/cm (± 3%) |

| Vessel Weight | 0-10 kg (± 0.3%) | 0-50 kg (± 0.3%) |

| Flow | 0-4 LPM (± 3%) | 0-8 LPM (± 3%) |

*Compressed air (oil free) @ 80 psi/5.5 bar

**Highest Operator interaction: 5 ft 2 in

Specifications represent standard Agilitech models and may change when customized for specific customer applications. Specifications subject to change without notice.

Floorstanding models - flow ranges up to 100 LPM

| Attribute | T500 | T750 | T1000 |

|---|---|---|---|

| General Skid Specifications | |||

| Tubing Internal Diameter | Feed and Retentate: 0.50 in Permeate: 0.25 in Inlets: 0.25 in |

Feed and retentate: 0.75 in Permeate: 0.50 in Inlets: 0.50 in |

Feed and retentate tubing: 1 in Permeate: 0.75 in Inlets: 0.75 in |

| Tank Size | Up to 200L | Up to 650 L | Up to 1000 L |

| Feed Flow Rate | 0-10 LMP (± 3%) | 0-50 LPM (± 3%) | 0-100 LPM (± 3%) |

| Pressure rating | 60 psi/4 bar | 60 psi/4 bar | 60 psi/4 bar |

| Temperature Range | 2-50°C | 2-50°C | 2-50°C |

| Humidity (non-condensing) | 10-90% | 10-90% | 10-90% |

| Utility Requirements* Skid Power Mixer Power |

100-120 VAC | 220-230 VAC 100 – 120 VAC |

220-230 VAC 100 – 120 VAC |

| Wetted Materials | USP <88> Class VI and animal free | USP <88> Class VI and animal free | USP <88> Class VI and animal free |

| Membrane Holder Capacity | 0.5m2 to 5.0m2 | 0.5m2 to 5.0m2 | 2.5m2 to 10.0m2 |

| Feed and Filtrate Flow Measurement | Clamp on ultrasonic flow sensor (±3%) | Clamp on ultrasonic flow sensor (±3%) | Clamp on ultrasonic flow sensor (±3%) |

| Temp Control | 2-50°C | 2 – 50°C | 2 – 50°C |

| Inlets | 1 product 2 buffers |

1 product 2 buffers |

To recirc bag: 3 inlets, 1 product, 2 buffers To feed pump: 3 inlets, 1 recirculating bag, 2 additional feed ports |

| Outlet Ports | 1 Filtrate | 1 Filtrate | Permeate: 2 outlets; waste or recycle Retentate; 3 outlets waste, recycle or recirculating bag |

| Minimum Working Volume Agitator Top Agitator Bottom Bag Sensors/Sampling |

Depends on mixer selected | Based on 2OO L Bag 37 L 14 L 25 L |

Based on 650 L Bag 82 L 31 L 55 L |

| Hold-Up Volume (excludes filtration device) |

750 mL | 1.5 L | 2.5 L |

| Dims (W x D x H)** Skid Bag Holder |

1219 x 787 x 1810 mm 1219 x 825 x 1595 mm |

1219 x 787 x 1810 mm 1219 x 825 x 1595 mm |

2032 x 1270 x 2108 mm 1371 x 1066 x 1595 mm |

| Sensor Performance | |||

| Pressure | 0-6 psi (± 2%) 6-30 psi (± 3%) 30-60 psi (± 5%) |

0 – 6 psi (± 2%) 6 – 30 psi (± 3%) 30 – 60 psi (± 5%) |

0 – 6 psi (± 2%) 6 – 30 psi (± 3%) 30 – 60 psi (± 5%) |

| Filtrate Conductivity | 0-250 mS/cm (±0.25 mS/cm) | 0-250 mS/cm (±0.25 mS/cm) | 0-250 mS/cm (± 0.25 mS/cm) |

| Vessel Weight | 0-200 kg (± 0.3%) | 0 -650 kg (± 3%) | 0-1000 kg (± 0.3%) |

| Flow | 0-10 LPM (± 3%) | 0-50 LPM (± 3%) | 0 – 100 LPM (± 3%) |

*Compressed air (oil free) @ 80 psi/5.5 bar

**Highest Operator interaction: 5 ft 2 in

Specifications represent standard Agilitech models and may change when customized for specific customer applications. Specifications subject to change without notice.

Download product information and other featured content:

Single-use Tangential Flow Filtration Systems

Scalable benchtop to large-scale models (882 KB)

Case Study

Biologics manufacturer optimizes TFF process to produce more biomaterial at a faster rate (4.9MB)

Agilitech Bioprocess Solutions Overview

Flexible and scalable single-use technologies (867 KB)

Quality manufacturing backed by full-service support

All Agilitech products are manufactured to the highest standards and delivered with the documentation you need:

- Standard Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) documentation provided upon delivery; we can also use your specific documentation, if preferred

- Installation Qualification (IQ) and Operational Qualification (OQ) testing and documentation available for use in cGMP production

- Performance Qualification (PQ) testing available, if needed

- Supplemental documentation provided, as needed, e.g., Qualification Project Plan (QPP), Criticality Assessment and Risk Assessment can also be provided

Agilitech products are also delivered with a recommended preventative maintenance plan and spare parts list. We also provide preventative maintenance service to ensure sensors and all other components continue to function at peak performance.

You have a vision for your process.

We can help you get there.