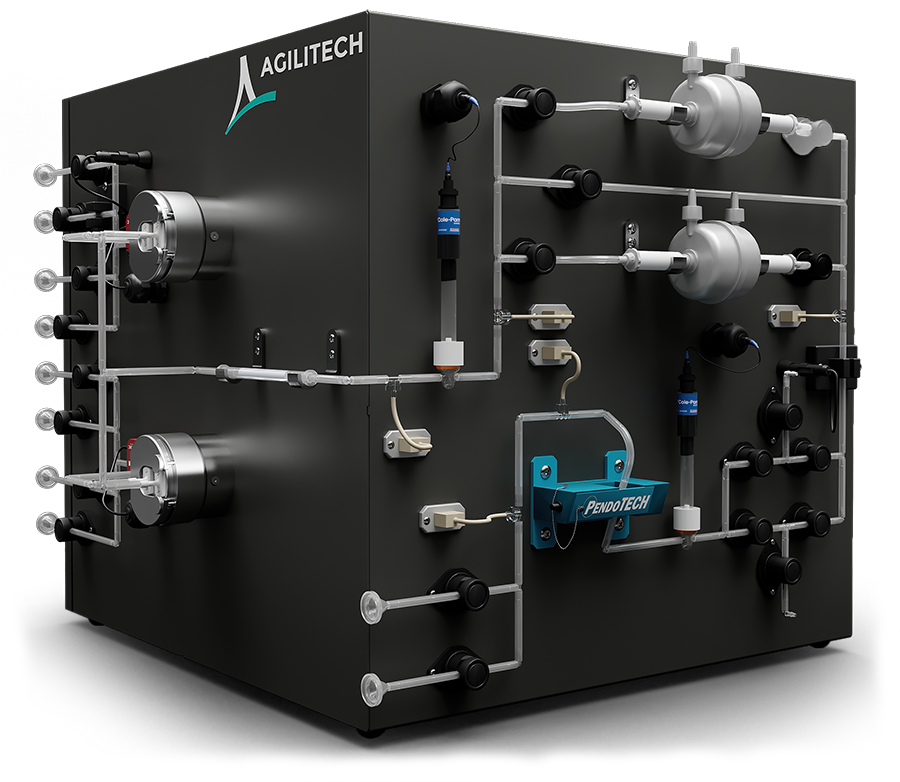

Single-Use Chromatography Systems Fit for Your Purpose

Standard chromatography design can be easily adapted to meet your needs today and in the future

Batch fed or continuous

Flexible automation

Brand-agnostic filters, columns, and other components

Adapts to your process requirements

Cost-effective scalability

Safe and sterile single-use technology

A choice of models

Designed to meet your exact requirements

We understand that every customer has unique requirements when selecting a chromatography system for their process. Many variables come into play: from load volume, flow rates and required inlets/outlets to the number of columns, UV wavelengths and more. That’s why one-size-fits-all solutions are suboptimal. Even out-of-the-box “customizable” chromatography systems fall short. There are always compromises with these solutions and they typically can’t be scaled or easily modified as requirements evolve.

Agilitech chromatography systems are engineered to fit the exact requirements of every customer. We consider your current and future needs in order to engineer the most efficient and robust chromatography system, tailored to you. Our chromatography systems are completely flexible and will grow with you as requirements change.

The brand-agnostic chromatography skid gives you unmatched options for filters, columns and other components—and even the control system.

Maximum flexibility

- Customize every aspect of the skid to meet your unique needs—whether it’s removing inlets/outlets, analytics, filters, columns, we can handle any combination of features/functions

- Column- and resin-agnostic—allows you to choose your preferred brand of columns/filters—whether Sartorius, Millipore, GE, Repligen or a custom pre-filter

- Flexible automation based on ISA 88 Standards for batch operations: run manually, load individual steps (Prime, Wash, Load, Elution, etc.) or run a fully automated sequence

- Run process in upflow or downflow

- Transition from flow control to pressure control, if needed (in case of filter fouling)

- Run, bind and elute, or flow through process steps

- Add multiple column connections for serial operation, if needed

Optimized performance and fit

The chromatography skid is engineered to accommodate any low flow rate requirements. The result: column sizes and resin quantities can be optimized for the specific process needs, keeping raw material costs as low as possible. A broad dynamic range enables optimization of skid size for every application. And, the combination of optimally sized inline analytical sensors and well-less measurement devices reduce hold up.

Single-use technology for a safe and sterile process

- Fully sterilized, single-use tubing set, complete with integrated sensors, minimizes risk of contamination

- Sterile-to-sterile connections for inlets/outlets reduce contamination risks

- Uses only the highest quality components, delivering USP <88> Class VI certified single-piece tubing sets that ensure sterility throughout use

Automation and control tailored to your needs

When it comes to automation for your chromatography system, our engineers are highly skilled with all the leading automation platforms, which includes state-of-the-art DeltaV. We are also a certified Rockwell System Integrator, and we have vast experience with Inductive Automation Ignition Software, Wonderware and other platforms. We use an ISA-88 structure to create the building blocks for automation, which ensures that the system is easy to use and feels the same, regardless of the platform.

Easy-to-use, intuitive control panel

We provide an interface that delivers a better user experience, because we solicited feedback from end users—and heard their frustrations. For example, the functions and data that operators told us they need to access most often are displayed on the top layer of the screen, eliminating endless clicking through menus and digging to access data.

Single-Use Chromatography Benchtop Models

Technical Specifications

| Attribute | C125 | C250 |

|---|---|---|

| General Skid Specifications | ||

| Tubing ID | 0.125 in | 0.25 in |

| Flow Rates | 1-500 mL/min | 16-3000 mL/min |

| Pressure | 0-60 psi/4 bar | 0-60 psi/4 bar |

| pH | 2-12 pH | 2-12 pH |

| Conductivity | 0-100 mS/cm | 0-100 mS/cm |

| UV Wavelength | 0-3 AU Dual Wavelength-280 nm and 300 nm standard. Customer configurable to any 2 wavelengths between 255-1000 nm | 0-3 AU Dual Wavelength-280 nm and 300 nm standard. Customer configurable to any 2 wavelengths between 255-1000 nm |

| Temperature Range | 2-50°C | 2-50°C |

| Humidity (non-condensing) |

10-90% | 10-90% |

| Utility Required, Skid Power* | 110-120 VAC | 110-120 VAC |

| Wetted Materials | USP <88> Class VI and animal free | USP <88> Class VI and animal free |

| Inlets | 8 (4 ea inlet header) | 8 (4 ea inlet header) |

| Outlets | 2 | 2 |

| Flow Accuracy | ±3% | ±3% |

| Hold-Up Volume-Inlet to Column | 50 mL | 95 mL |

| Hold-Up Volume-Column to Outlet | 10 mL | 36 mL |

| Dims (W x D x H)** | 610 x 610 x 610 mm | 610 x 610 x 610 mm |

| Sensor Performance | ||

| Pressure | 0-6 psi (± 2%) 6-30 psi (± 3%) 30-60 psi (± 5%) |

0-6 psi (± 2%) 6-30 psi (± 3%) 30-60 psi (± 5%) |

| Conductivity | 0-100 mS/cm (± 5%) | 0-100 mS/cm (± 5%) |

| Flow | 0-4 LPM (± 3%) | 0-8 LPM (± 3%) |

| pH | 2-12 pH (± 0.1) | 2-12 pH (± 0.1) |

| UV | 0-2 AU (± 1%) 2-3 AU (± 2%) |

0-2 AU (± 1%) 2-3 AU (± 2%) |

*Compressed air (oil free) @ 80 psi/5.5 bar

**Highest Operator interaction: 5 ft 2 in

Specifications represent standard Agilitech models and may change when customized for specific customer applications. Specifications subject to change without notice.

Quality manufacturing backed by world-class service and support

All Agilitech single-use chromatography systems are manufactured to the highest standards and delivered with the documentation you need:

- Standard Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) documentation provided upon delivery; we can also use your specific documentation, if preferred

- Installation Qualification (IQ) and Operational Qualification (OQ) testing and documentation available for use in cGMP production

Agilitech single-use chromatography systems are delivered with a recommended preventative maintenance plan and spare parts list. We also provide preventative maintenance service to ensure pumps, transmitters and all other components continue to function at peak performance.

You have a vision for your process.

We can help you get there.