Flexible Single-Use Technologies for Your Bioprocess

Shaped by you and poised to evolve

Single-use systems that are redefining flexiblity in bioprocessing

The benefits of single-use technologies in bioprocessing are well known and include: time savings, increased process flexibility, reduced risk of cross-contamination, easy disposal and other operational efficiencies. Agilitech single-use technologies are designed to provide all of these benefits—and much more.

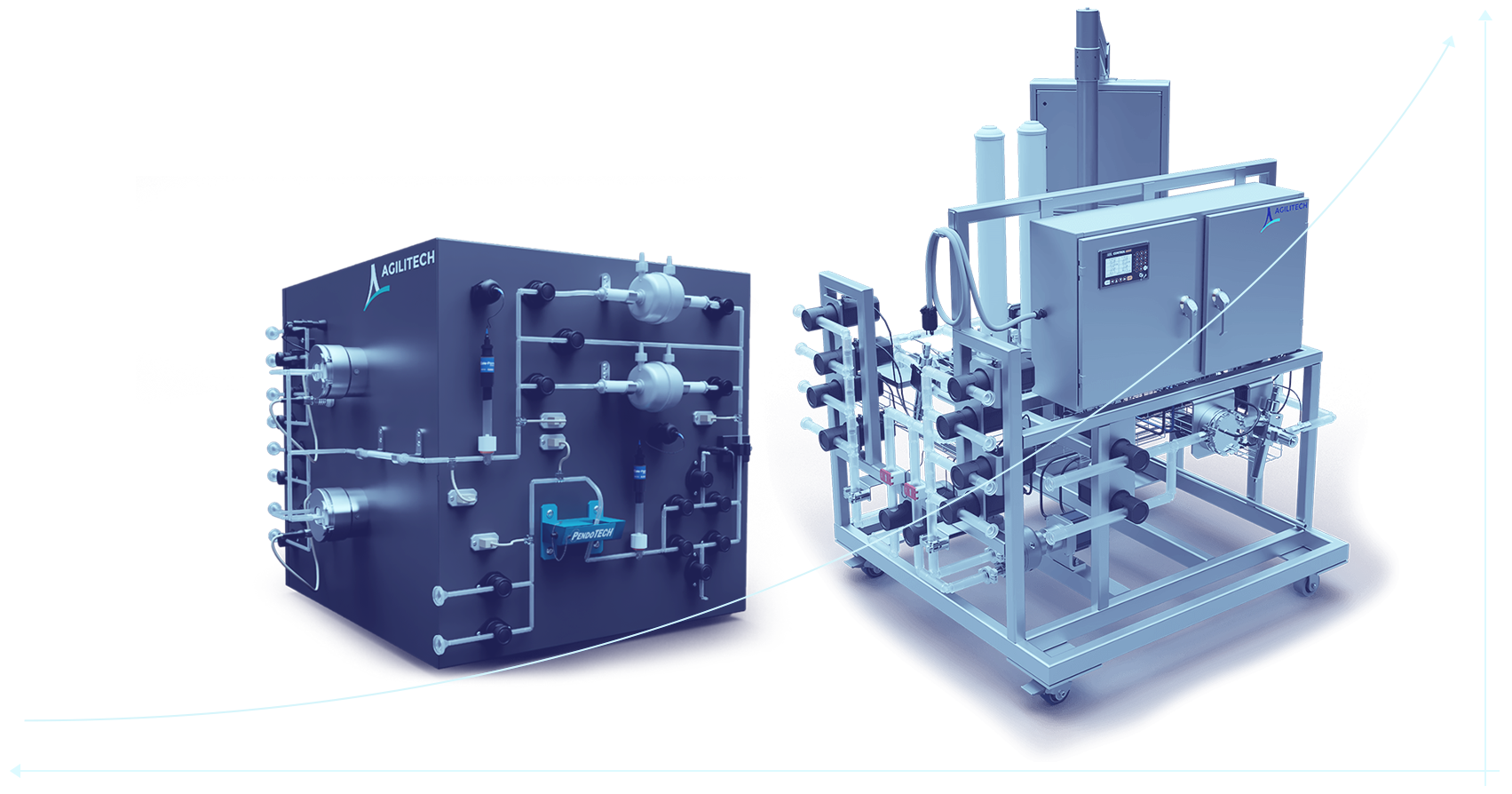

A wide range of scalable single-use solutions for research to pilot and full scale production

Agilitech single-use systems maximize process efficiencies, reduce cost, and accelerate drug development as well as production. Our bioprocessing solutions include single-use chromatography systems and a full range of single-use filtration solutions, including sterile filtration, depth filtration, virus filtration, and tangential flow filtration (TFF) systems. We also offer custom-tailored bioprocess controllers for lab and production environments. For more information about specific Agilitech single-use products, click the links at right.

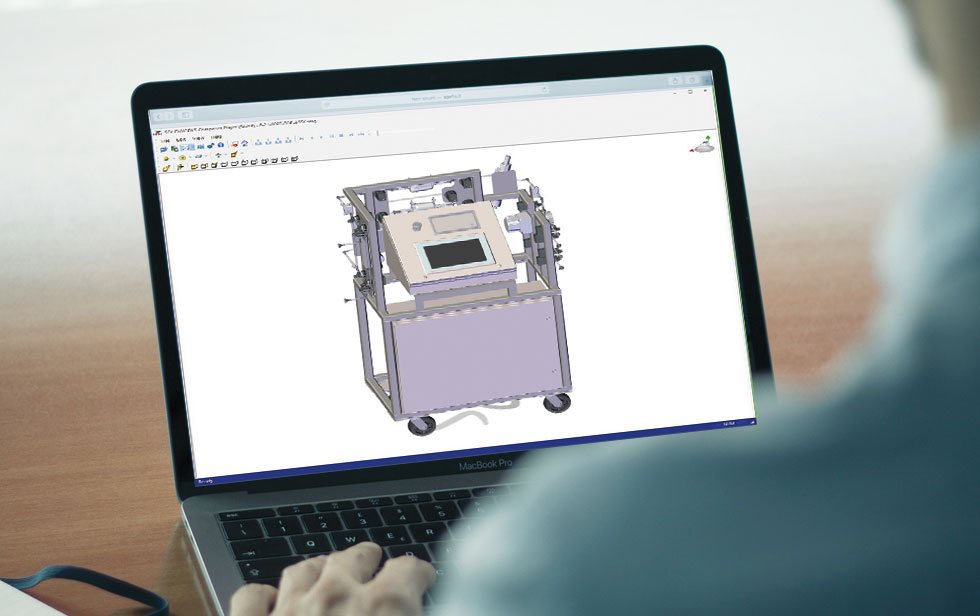

A revolutionary approach to product design and engineering

A transformative product design and engineering process is what makes Agilitech single-use products unique and ensures they meet the exact needs of each and every customer.

Our unique collaborative front-end planning and product design process starts with you. We invest the time up front to understand your current needs and future development goals before adapting our standard single-use technologies to fit your purpose.

Agilitech’s product development team works through an iterative design process with you to model a single-use product solution that meets your current and future process needs. Based on that custom-tailored design, we provide a proposal for the best-fit solution along with options for support services. Once you approve the design model, we move swiftly to build your system. Standard Factory Acceptance Testing (FAT) and system qualification (IQ/OQ) are performed before the system leaves our facility to streamline delivery and ensure it is ready for use upon installation.

Interested in single-use technologies for your bioprocess?

Request a call with an Agilitech product expert.

Bioreactor Controllers

For stirred-tank vessels up to 20 L

For rockers up to 50 L

Bioreactor Controllers

For single-use bioreactors up to 2000 L

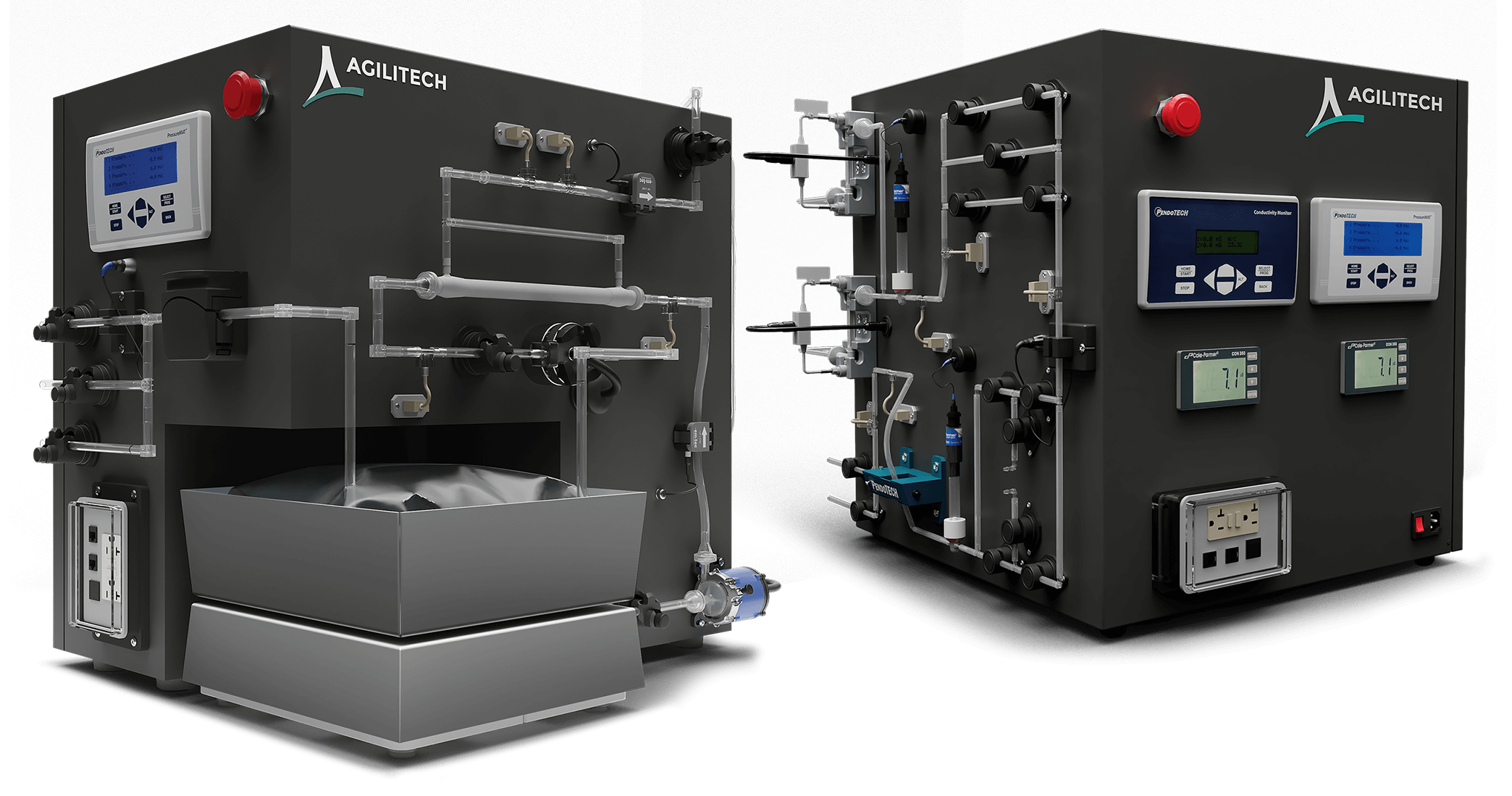

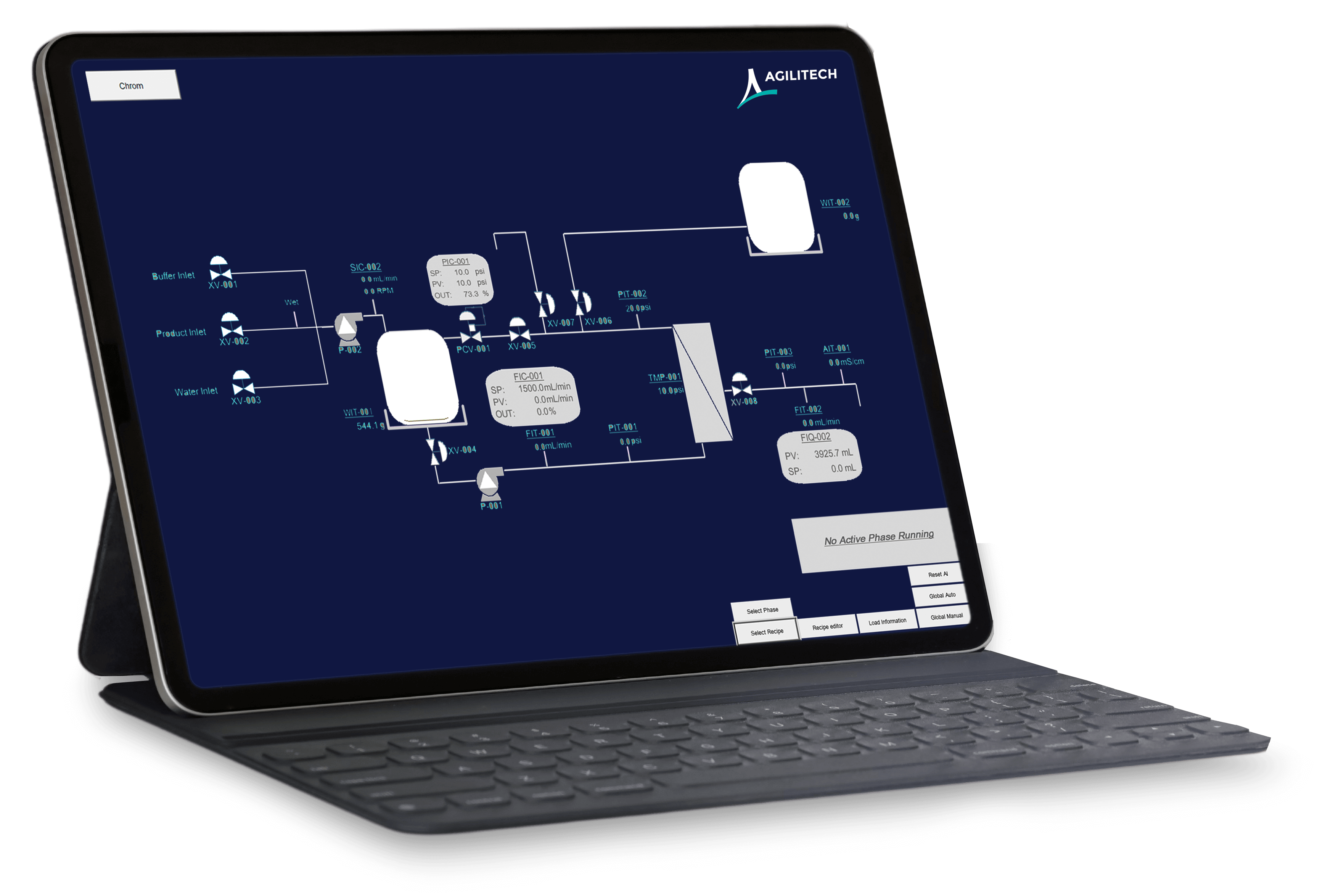

Chromatography Systems

Benchtop models up to 3.1 LPM flow

Chromatography Systems

Floor standing models up to 41 LPM flow

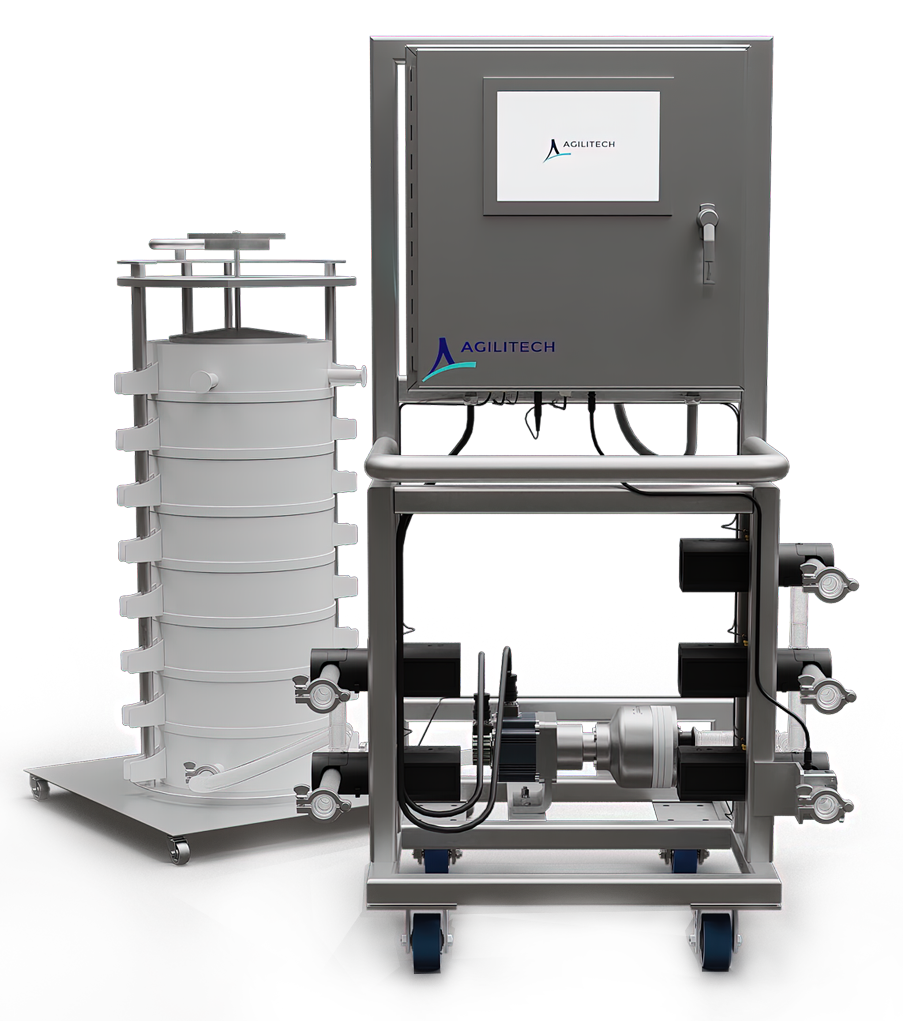

Scalable Chromatography System

Configurable for 0.25 and 0.50 inch tubing

Up to 15 LPM flow

Depth Filtration Systems

Inline Dilution Systems

Mixers

Multipurpose Filtration Systems

- Sterile Filtration

- Depth Filtration

- Virus Filtration

Sterile Filtration System

Tangential Flow Filtration Systems

Benchtop models up to 7.7 LPM flow

Tangential Flow Filtration Systems

Floor standing models up to 100 LPM flow

Virus Filtration Systems

Unmatched flexibility in design and engineering

Our uniquely designed single-use systems provide complete flexibility to meet your exact bioprocess requirements. We don’t expect you to fit your process to our technology—instead, we tailor fit our single-use systems to your exact bioprocessing needs.

It’s not just about small system modifications. Agilitech single-use systems are designed to enable modifications of core components; for example, we can reconfigure the flow path of our standard single-use chromatography system to add more filters, outlets, and/or buffers, and we can adapt our standard single-use TFF system to accommodate different filter sizes in the same skid.

Scalable single-use systems from lab to production

Agilitech single-use technologies can be scaled from lab to pilot and full-scale production. We offer unique scalable chromatography and TFF systems that take flexibility to a whole new level. The scalable system can be used at small scale and the same system later adapted for larger-scale production with minimal modification. This unique technology (patent pending) not only streamlines the scale-up process, but also eliminates the need to purchase an entirely new skid at each scale-up stage.

Whether it’s changing out core components or adapting to scale up, the in-built flexibility of our solutions is led and shaped by your current needs and where you’re headed in the future.

Brand-agnostic design for a best-in-class system

Agilitech single-use systems are designed to be completely brand agnostic. We can accommodate your specific brand preferences, while best-in-class filters and components are used for every aspect of the skid; for example, our multipurpose single-use filtration system can be adapted to virtually any brand external filtration system, and we can adapt different filter and sensor brands to our TFF and chromatography systems. We can integrate the filters and components that are ideally suited for your bioprocess and align with your brand preferences. This results in a unique and truly best-in-class system that is fit perfectly for your purpose. Another significant benefit of the Agilitech brand-agnostic approach: if there are supply issues with a particular filter or other component, we have the option to accommodate alternatives. You are not locked in to a specific product brand or vendor—true flexibility in design.

ISA S88 compliant design enables both manual and automated operation

Agilitech single-use systems are designed to provide complete flexibility when it comes to process automation and control. An ISA-88 batch-compliant structure is used, which enables you to run a manual, semi-automated, or fully-automated process—the choice is yours. This built-in flexibility is particularly beneficial for process development scientists who prefer to start out using the system in manual mode and then adding automation as they evolve their process.

Flexible and seamless integration with your preferred automation and control platform

Agilitech single-use systems can be adapted to any modern automation and control platform—whether that’s DeltaV®, Rockwell Automation®, or another platform. Our product design and engineering team has deep knowledge and experience with a wide range of automation and control platforms to ensure seamless integration with your existing systems. And we never lock down your single-use system, giving you the freedom to make modifications on your own if you have the resources in place to do so. Regardless of the platform you choose, the user experience is the same due to the ISA-88 batch-compliant structure that is used to create the building blocks of the automation.

Quality manufacturing backed by world-class service and support

All Agilitech single-use systems are manufactured to the highest standards and delivered with the documentation you need:

- Standard Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) documentation provided upon delivery; we can also use your specific documentation, if preferred

- Installation Qualification (IQ) and Operational Qualification (OQ) testing and documentation available for use in cGMP production

Agilitech single-use systems are delivered with a recommended preventative maintenance plan and spare parts list. We also provide preventative maintenance service to ensure that your system continues to function at peak performance.

Related Content

DOWNSTREAM COLUMN BLOG: Flexible Single-Use Technology that Adapts to an Evolving Industry

One thing constant in biopharmaceutical manufacturing is change. There is an ever-present need to adapt to new therapeutic modalities, more cost-effective approaches, higher product demands, and even a worldwide pandemic.

PODCAST: Addressing the increasing demand for single-use technologies and supply chain shortages with future-proof systems

We’re pleased to share this new podcast recently published by Downstream Column; a conversation about single-use technologies.

CASE STUDY: Biologics manufacturer seeks to optimize its tangential flow filtration system to process more biomaterial at a faster rate

A leader in the production of enzymes for molecular biology applications needed a new TFF system to increase production of its cell-based product. Learn how Agilitech collaborated with the customer’s team to develop a future-proof system designed to meet current needs and double throughput in the future.

Want to learn more about the Agilitech single-use sterile filtration system?

Please complete this form and an Agilitech specialist will be in touch.