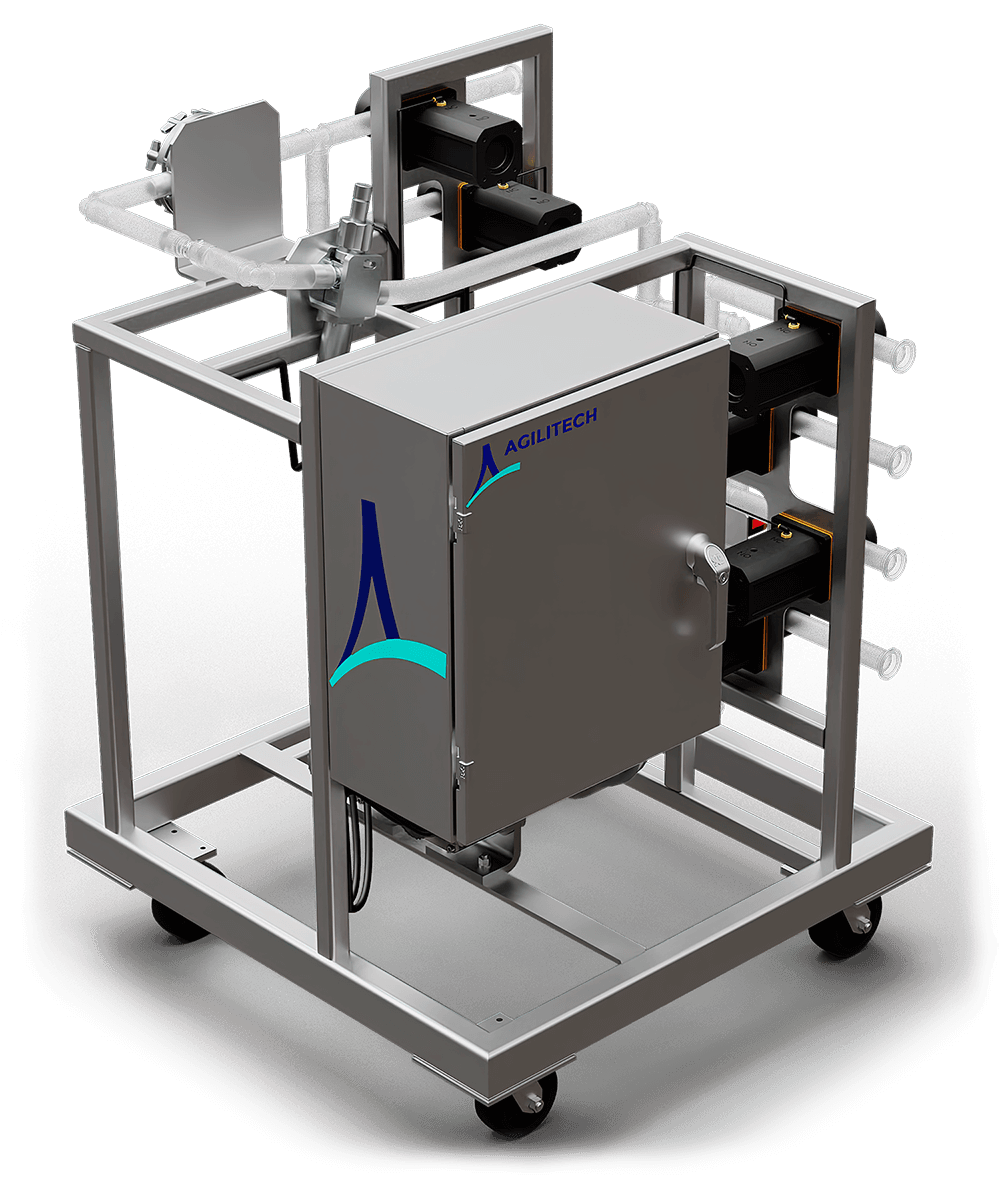

Automated Single-Use Inline Buffer Dilution System

De-bottleneck your downstream bioprocess with automated inline buffer preparation and delivery.

Precise and reproducible buffer preparation with just-in-time delivery at point of use

Minimize manual labor associated with traditional buffer preparation

Reduce buffer hold capacity requirements to save space

Inline static mixer with back-pressure regulator ensures stable mixing

Dual inlet header with Quattroflow pumps on each header

Three models to handle flow rates from 0.167 LPM to 41 LPM

Streamline buffer preparation and delivery to optimize your downstream bioprocess

The Agilitech single-use inline dilution system provides a cost-effective and streamlined alternative to traditional manual buffer preparation and management. With traditional buffer preparation, large quantities of multiple buffers are manually prepared and stored for later use. This process is both time consuming and requires adequate space for storage of the prepared buffer solution until it is used. In contrast, there is no buffer preparation and storage with the Agilitech automated single-use inline dilution system.

The concentrated buffer solution is diluted in a single-use mixer that is integrated into your downstream bioprocess. The Agilitech system controls dilution of the highly concentrated buffer and ensures precise just-in-time delivery at the point of use in your process. This automated process results in more efficient use of existing resources, including labor and reagents, as well as a smaller facility footprint. It also eliminates the risk of operator errors associated with manual buffer preparation and management.

Best-in-class components for optimized performance

Agilitech’s standard inline dilution system features dual inlet headers with a Quattroflow pump on each header; 1 inlet is dedicated to water for injection/purified water and the other is customized for multiple buffers. The standard system can accommodate additional inlets and pumps, if needed.

The inline dilution system also features pH/condo measurements. Control going to waste or destination is based on pH/condo values. (Note that condo control is an optional feature.)

No proprietary software puts you in control

The inline dilution system can be adapted to any modern automation and control platform—whether that’s DeltaV®, Rockwell Automation®, or another platform. And we never lock down the system, which enables you to make modifications on your own.

Inline Dilution Skid Models

Technical Specifications

| Attribute | D500 | D750 | D1000 |

|---|---|---|---|

| General Skid Specifications | |||

| Tubing ID | 0.50 in | 0.75 in | 1.0 in |

| Flow Rates | 0.167-15 LPM | 0.167-20 LPM | 0.8-41 LPM |

| Pressure | 0-60 psi/4 bar | 0-60 psi/4 bar | 60 psi/4 bar |

| pH | 0-14 pH | 0-14 pH | 0-14 pH |

| Conductivity | 0-250 mS/cm | 0-250 mS/cm | 0-250 mS/cm |

| Temperature Range | 2-50°C | 2-50°C | 2-50°C |

| Humidity (non-condensing) | 10-90% | 10-90% | 10 – 90% |

| Utility Required, Skid Power* | 220-230 VAC | 220-230 VAC | 220-230 VAC |

| Wetted Materials | USP <88> Classs VI and animal free | USP <88> Class VI and animal free | USP <88> Class VI and animal free |

| Inlets | 1 Water, 4 Buffer | 1 Water, 4 Buffer | 1 Water, 4 Buffer |

| Outlets | 2 | 2 | 2 |

| Flow Accuracy | ±3% | ±3% | ±3% |

| Dims (W x D x H)** | 910 x 910 x 1025 mm | 1622 x 1422 x 1816 mm | 1622 x 1422 x 1816 mm |

| Sensor Performance | |||

| Pressure | 0-6 psi (± 2%) 6-30 psi (± 3%) 30-0 psi (± 5%) |

0-6 psi (± 2%) 6-30 psi (± 3%) 30-0 psi (± 5%) |

0-6 psi (± 2%) 6-30 psi (± 3%) 30-60 psi (± 5%) |

| Conductivity | 0-250 mS/cm (±0.25 mS/cm) | 0-250 mS/cm (±0.25 mS/cm) | 0-250 mS/cm (±0.25 mS/cm) |

| Flow | 0-20 LPM (± 3%) | 0-50 LPM (± 3%) | 0-100 LPM (± 3%) |

| pH | 0-14 (± 0.1) | 0-14 (± 0.1) | 0-14 (± 0.1) |

*Compressed air (oil free) @ 80 psi/5.5 bar

**Highest Operator interaction: 5 ft 2 in

Specifications represent standard Agilitech models and may change when customized for specific customer applications. Specifications subject to change without notice.

Quality manufacturing backed by world-class service and support

All Agilitech products are manufactured to the highest standards and delivered with the documentation you need:

- Standard Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) documentation provided upon delivery; we can also use your specific documentation, if preferred

- Installation Qualification (IQ) and Operational Qualification (OQ) testing and documentation available for use in cGMP production

Agilitech bioprocess controllers are also delivered with a recommended preventative maintenance plan and spare parts list. We also provide maintenance service to ensure your system is always operating at peak performance.

You have a vision for your process.

We can help you get there.