Resources

Biotech Industry Insights

ARTICLE: Staying Ahead of a Constantly Evolving Biologics Industry

Iinsights on the best ways to ensure efficient biomanufacturing while responding to changing priorities, new opportunities, and increasing demands.

ARTICLE: Future Proofing Upstream Bioprocess Operations

Upstream bioprocessing has evolved and new technology along with supply and demand changes present big challenges. This article provides case study examples of how Tezalon collaborated with customers to provided flexible, fit-for-purpose upstream solutions.

ARTICLE: Future Proofing Downstream Bioprocess Operations

This article examines how to future proof downstream bioprocessing. Case study examples highlight how Tezalon designed downstream systems that are flexible and adaptable to meet the needs of future advancements and challenges.

ARTICLE: Upstream and Downstream Bioprocesses - A Holistic View

A discussion of best practices for creating a holistic process from upstream to downstream – whether you’re building from the ground up or creating a unified system using existing equipment and processes.

PODCAST: Single-Use Mixers – Ensuring the Customization, Scalability and Supply Required for Success

We’re pleased to share this new podcast recently published by Downstream Column; a conversation about single-use mixers.

DOWNSTREAM COLUMN BLOG: Flexible Single-Use Technology that Adapts to an Evolving Industry

One thing constant in biopharmaceutical manufacturing is change. There is an ever-present need to adapt to new therapeutic modalities, more cost-effective approaches, higher product demands, and even a worldwide pandemic.

PODCAST: Addressing the increasing demand for single-use technologies and supply chain shortages with future-proof systems

We’re pleased to share this new podcast recently published by Downstream Column; a conversation about single-use technologies.

PODCAST: Guide for Navigating the Single Use Technology Supply Chain (400 KB)

We’re pleased to share this new podcast recently published by Downstream Column.

PODCAST: Upstream and Downstream Processes - A Holistic View

We’re pleased to share this new podcast recently published by Cell Culture Dish

Article Reprints

Future-proof Bioprocess: flexible single-use technology that adapts to an evolving industry

(133KB)

Addressing the increasing demand for single-use technologies and supply chain shortages with future proof systems

(113KB)

Achieving Peak Flexibility – A single-use filtration skid with multiple application capability (depth filtration, virus filtration, sterile filtration)

(304 KB)

Single-use Mixers – Ensuring the Customization, Scalability and Supply Required for Success

(198 KB)

Guide for Navigating the Single-use Technology Supply Chain

(400 KB)

Product Case Studies, White Papers, and Other Tezalon Content

NEW CASE STUDY: Biologics Manufacturer Seeks 1OOOL Break Tank for Accurate Control of WFI Delivery to Inline Dilution Skid

A recognized leader in contract drug manufacturing sought a stable supply of up to 1000L of WFI for their single-use inline dilution skid. Tezalon designed a portable 1000L single-use tote with precise weighing capabilities, robust construction, and integrated filtration. Using advanced technologies, Tezalon provided a versatile and future-proof solution, demonstrating their commitment to innovation and process optimization.

NEW CASE STUDY: Pharmaceutical Research Company Seeks Elegant Solution to Weigh Single-Use Bioreactor Feed Bottles

A pharmaceutical research lab faced the challenge of accurately weighing bioreactor transfer feed bottles while preserving benchtop space. With eight bioreactors, each fed by four peristaltic pumps, the lab needed a solution that integrated seamlessly with their existing DeltaV infrastructure.The design process involved creating a compact, versatile system with a minimal footprint. The final design featured enclosure-mounted load cells elevated above existing pump towers and adaptable 3D-printed nylon bottle holders.This innovative solution maximized space efficiency and improved bioreactor feeding accuracy, impressing the customer with its seamless integration and custom design.

APPLICATION NOTE: Solvation Studies with Tezalon Single-Use Mixers

Our recent studies have demonstrated that Tezalon’s 10L single-use mixers excel in managing solvation and viscosity challenges across various solutes, including NaCl, NaOH, glucose, HEPES, IgG, and polysorbate 80. These mixers not only ensure macromolecular integrity but also offer reliable temperature control, making them an ideal choice for bioprocess development and manufacturing.

Tezalon Bioprocess Solutions Literature

Upstream Bioprocessing

Bioreactor Controllers

For bioreactors up to 50 L (478KB)

Bioreactor Controllers

For Bioreactors up to 2000 L (1.7MB)

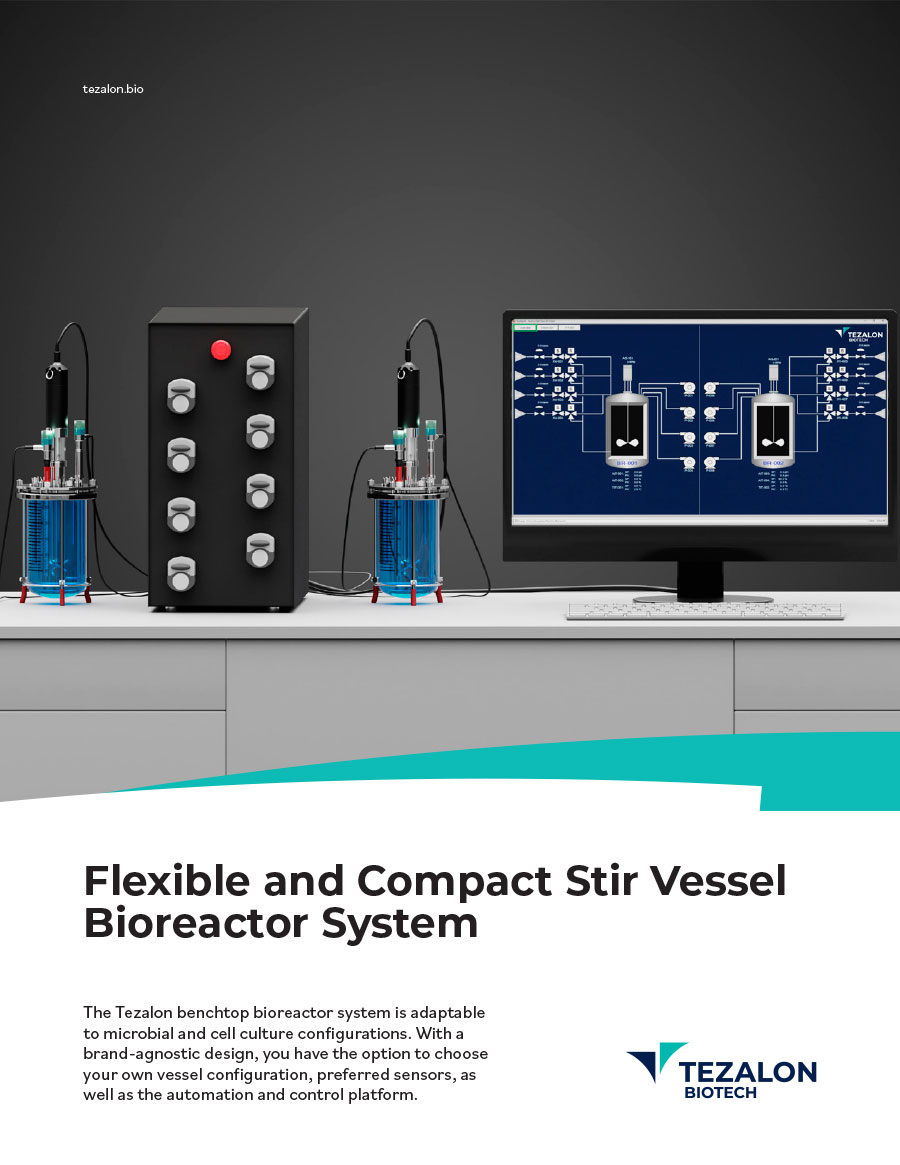

Bioreactor Systems

Stir vessels up to 20 L (561KB)

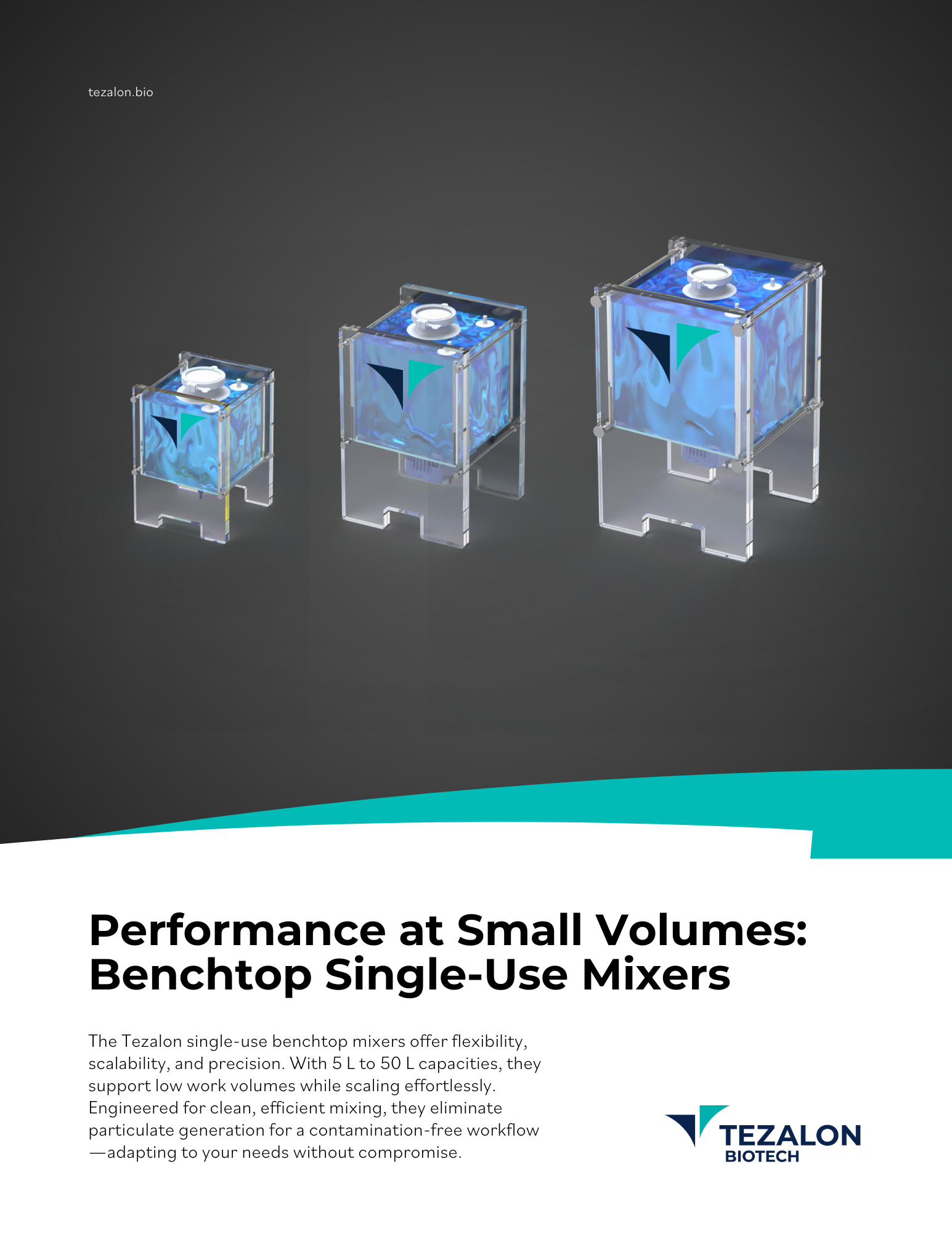

Single-Use Mixers

Available in multiple models ranging from 5 L to 5000 L

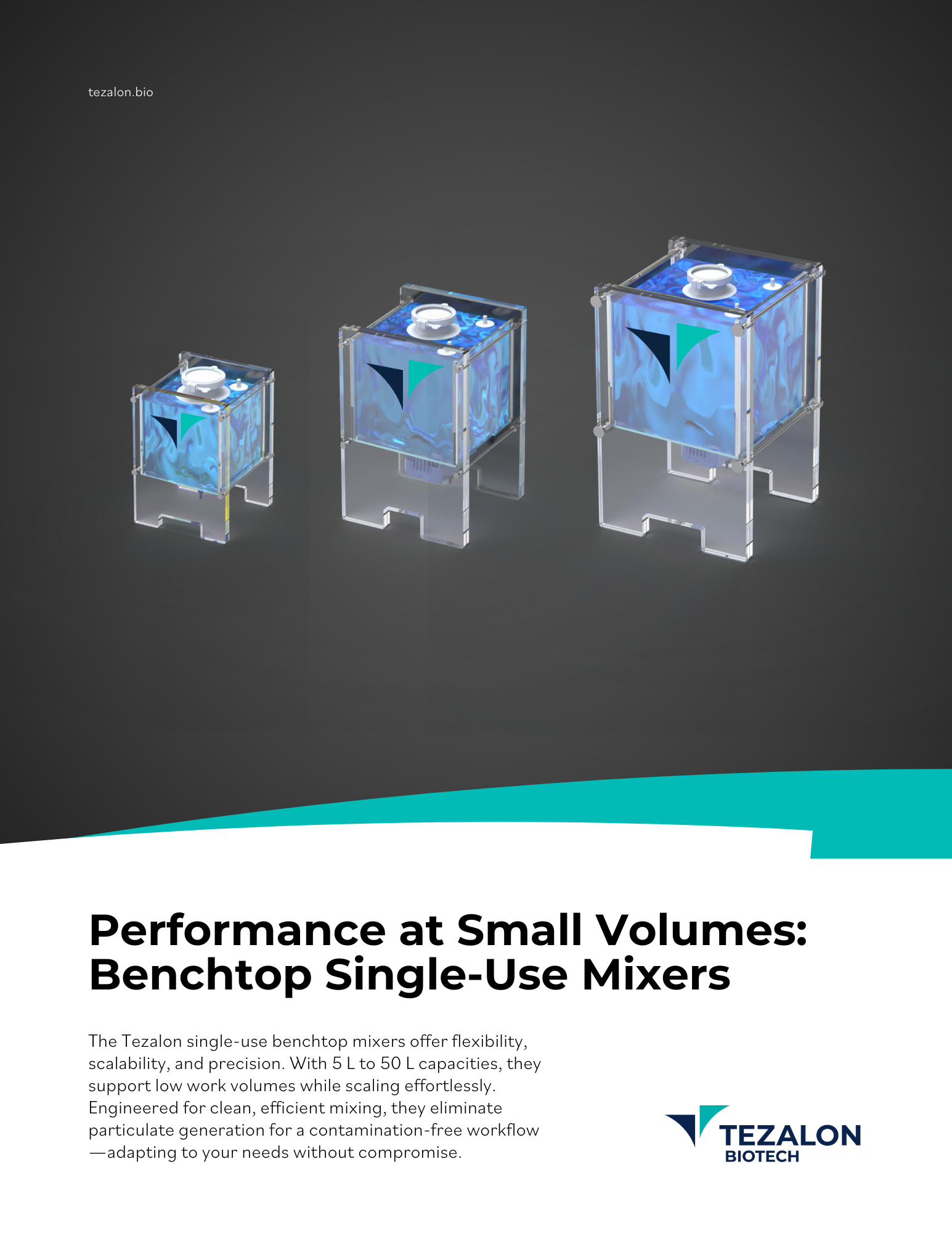

Portable Benchtop Mixers

Performance at Small Volumes

Downstream Bioprocessing

Single-use Multipurpose Filtration Systems

Configurable for Depth, Virus, Sterile Filtration

1.1 MB

Single-use Tangential Flow Filtration Systems

Scalable benchtop to large-scale models (882 KB)

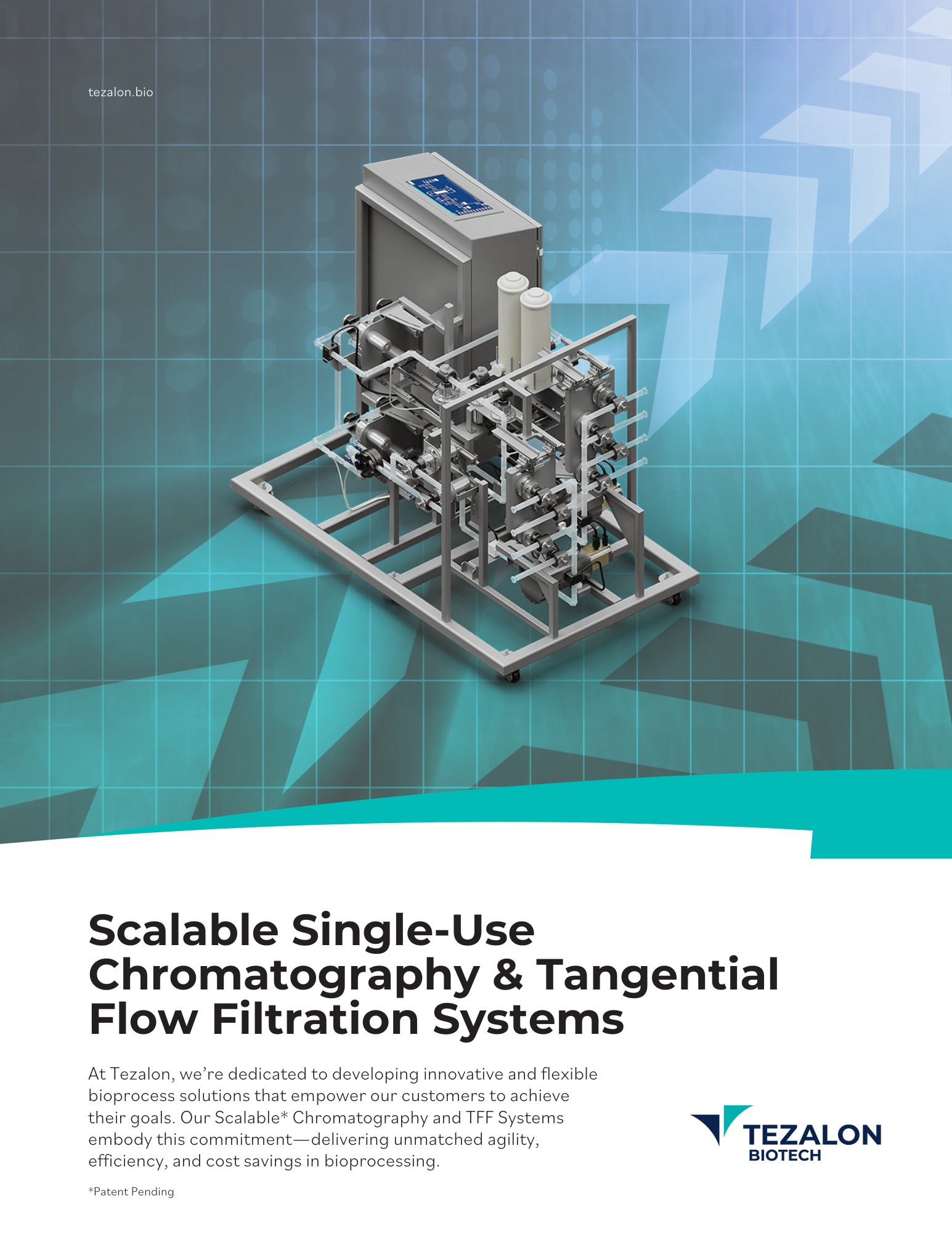

Scalable Single-Use Chromatography and Tangential Floe Filtration Systems

with Tezalon patent pending scalable technology

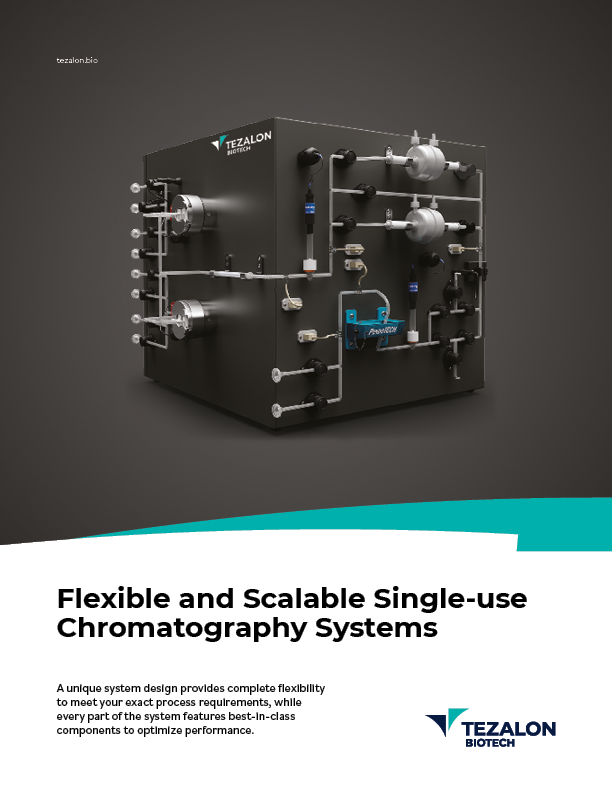

Flexible & Scalable Single-Use Chromatography System

From benchtop to large scale: chromatography systems to meet your exact needs

Single-use Inline Dilution System

De-bottleneck your bioprocess (558 KB)

Single-Use Mixers

Available in multiple models ranging from 5 L to 5000 L

Portable Benchtop Mixers

Performance at Small Volumes

Benchtop Tangential Flow FIltration (TFF)

From manual operation to recipe automation: Tezalon TFF systems meet your exact needs

Join our mailing list!

Get email updates about new products, special promotions, and more. Please complete and submit the form below. You can unsubscribe at any time.