Flexible and Compact Dual Bioreactor Controller

For any brand stirred-tank bioreactor up to 20 L and rocking bioreactors up to 50 L

Compatible with fermentation and cell culture vessel configurations

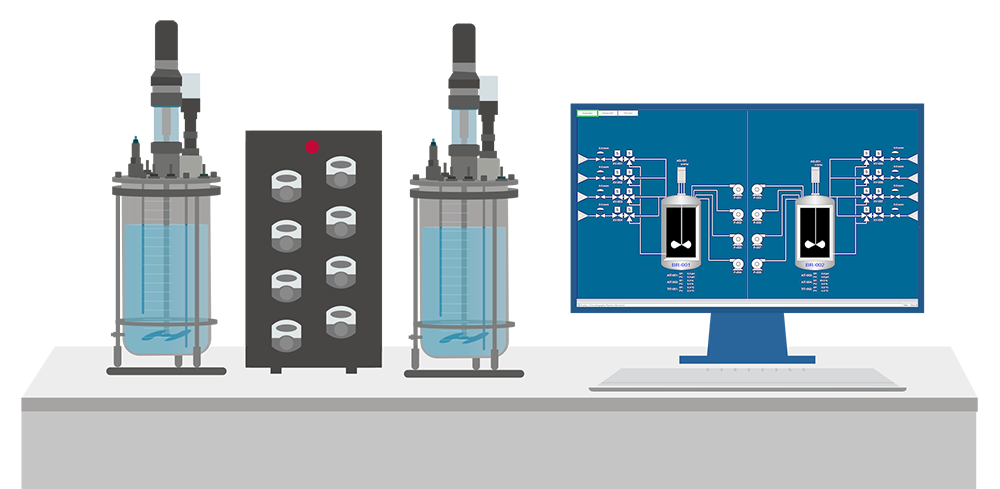

Simultaneous control of two stirred-tank vessels or two rocking bioreactors

Brand-agnostic design: use your own vessels or single-use bags and preferred sensors

Delivered with your preferred control system: DeltaV, Rockwell Automation, or other

Flexible operation: manual mode to fully automated batch operations

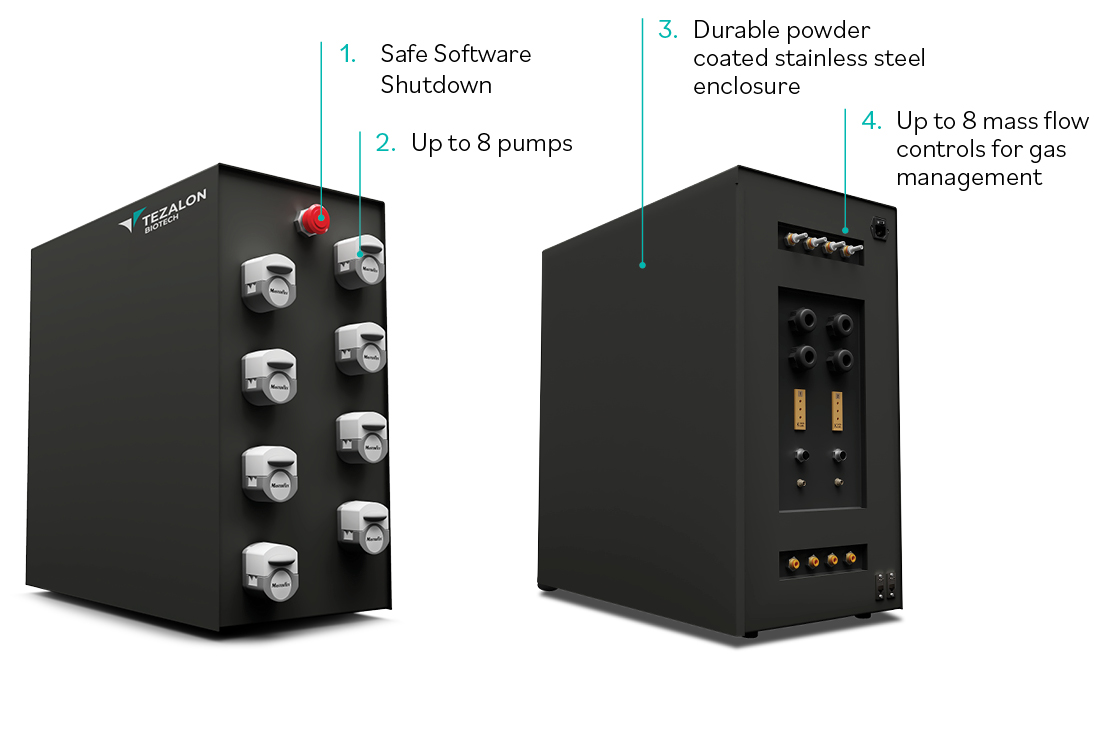

Easy access to agitator motor adapters

Up to 8 pumps for fluid management

Up to 8 mass flow controls for gas management

Flexible design: add scales for vessel weights or addition monitoring

Simultaneous control of two bioreactors

Designed with flexibility in mind, the Tezalon bioreactor controller is adaptable to both fermentation and cell culture configurations. It can be configured with up to 8 pumps (4 for each bioreactor) and up to 8 mass flow controllers for gas measurement (4 for each bioreactor), offering simultaneous control of two vessels. The controller is compatible with glass stir vessels up to 20L and rocking bioreactors with single-use bags up to 50L.

Unique brand-agnostic design

The bioreactor controller can be used with any manufacturer brand bag or glass vessel, including the agitator motor adapters for different types of vessels and impellers. It can also be adapted to your existing equipment and automation/control platform. The controller provides an ideal solution for updating outdated controllers, while extending the lifetime of your existing fully-functional bioreactors. The system is also brand agnostic when it comes to sensors, giving you the freedom to choose the right sensor for your unique bioprocess, whether that’s Mettler Toledo, Broadley James, Hamilton, PreSens, or another sensor brand.

Space-saving compact design

Components are protected with a durable stainless steel housing and a compact footprint saves valuable bench space. The control system also accommodates additional scales for vessel weight and additional sensors for perfusion applications.

ISA-88 standards for maximum flexibility

Controls are based on an ISA-88 batch-compliant structure, which enables manual or automated operation.

Future-proof bioprocess control

The built-in flexibility of the controller design is ideally suited for evolving process development environments; you can start out using the system in manual mode as you develop your process and then move toward integration into a larger DCS as you refine your process. And other modifications are possible after the controllers are initially implemented; for example, accommodating antifoam requirements as your process evolves.

No proprietary software puts you in control

The bioreactor controller can be integrated with any modern automation and control platform—whether that’s DeltaV®, Rockwell Automation®, or another platform. And we never lock down the system, which enables you to make modifications on your own as your process evolves. Using ISA-88 structure to create the building blocks for automation also ensures that the system is easy to use and feels the same, regardless of the platform.

Eliminate “islands of automation” in your bioprocess

Many bioprocessing labs have standalone equipment that is controlled locally or several pieces of equipment from the same manufacturer that are connected, but no unified platform that controls the entire bioprocess. This results in “islands of automation” with different levels of control that are disconnected from the rest of the process and leads to data silos and a variety of other issues. The end result is an inefficient overall process and costly workarounds to bridge the gap.

Since Tezalon bioprocess controls are based on an ISA-88 batch-compliant structure and we use open industrial platforms and not proprietary software, we can integrate your existing equipment into a single unified platform. The Tezalon approach to bioprocess control also provides assurances for the future as your process evolves.

Technical Specifications

| Attribute | Stir Vessel Configuration | Rocker Configuration |

| Dimensions | 24.8 x 24 x 12.6 in (H x D xW) | 24.8 x 24 x 12.6 in (H x D xW) |

| Operating Temp. | 5 – 40°C | 5 – 40°C |

| Relative Humidity | 5 – 95% | 5 – 95% |

| Agitation | Variable Speed Servo Motor with Agitator Blade Adapters |

2-40 RPM 2-12 Degree |

| pH / DO | Mettler Toledo, Broadley James, Hamilton, Endress Hauser |

preSens |

| Temp | 100 Ohm RTD in thermowell | 100 Ohm RTD in thermowell |

| Liquid Control | 8x Cole Parmer Miniflex Variable (0-330 mL/min depending on tubing dimensions) | 8x Cole Parmer Miniflex Variable (0-330 mL/min depending on tubing dimensions) |

| Temperature Control | Heating Blanket; 3-way solenoid valve for chilled liquid, if applicable |

Tray heater; no cooling |

| Gas Control | 8x MFC with direction control for overlay or sparge | 8x MFC with combined flow to rocker bag |

| Scale/Balance | Not in base solution, but can add | Not in base solution, but can add |

| Antifoam | Not in base solution, but can add | Not in base solution, but can add |

| Glass Vessels | 1 – 20 L | Not Applicable |

| Single-Use Vessels | 1.3 – 14 L | Not Applicable |

| Rocker | Not Applicable | 10 – 50 L |

| Vent Filter Heater | Not Applicable | Yes |

Quality manufacturing backed by world-class service and support

All Tezalon products are manufactured to the highest standards and delivered with the documentation you need:

- Standard Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) documentation provided upon delivery; we can also use your specific documentation, if preferred

- Installation Qualification (IQ) and Operational Qualification (OQ) testing and documentation available for use in cGMP production

- Performance Qualification (PQ) testing available, if needed

- Supplemental documentation provided, as needed, e.g., Qualification Project Plan (QPP), Criticality Assessment and Risk Assessment can also be provided

Tezalon bioreactor controllers are delivered with a recommended preventative maintenance plan and spare parts list. We also provide preventative maintenance service to ensure sensors and all other components continue to function at peak performance.

You have a vision for your process.

We can help you get there.