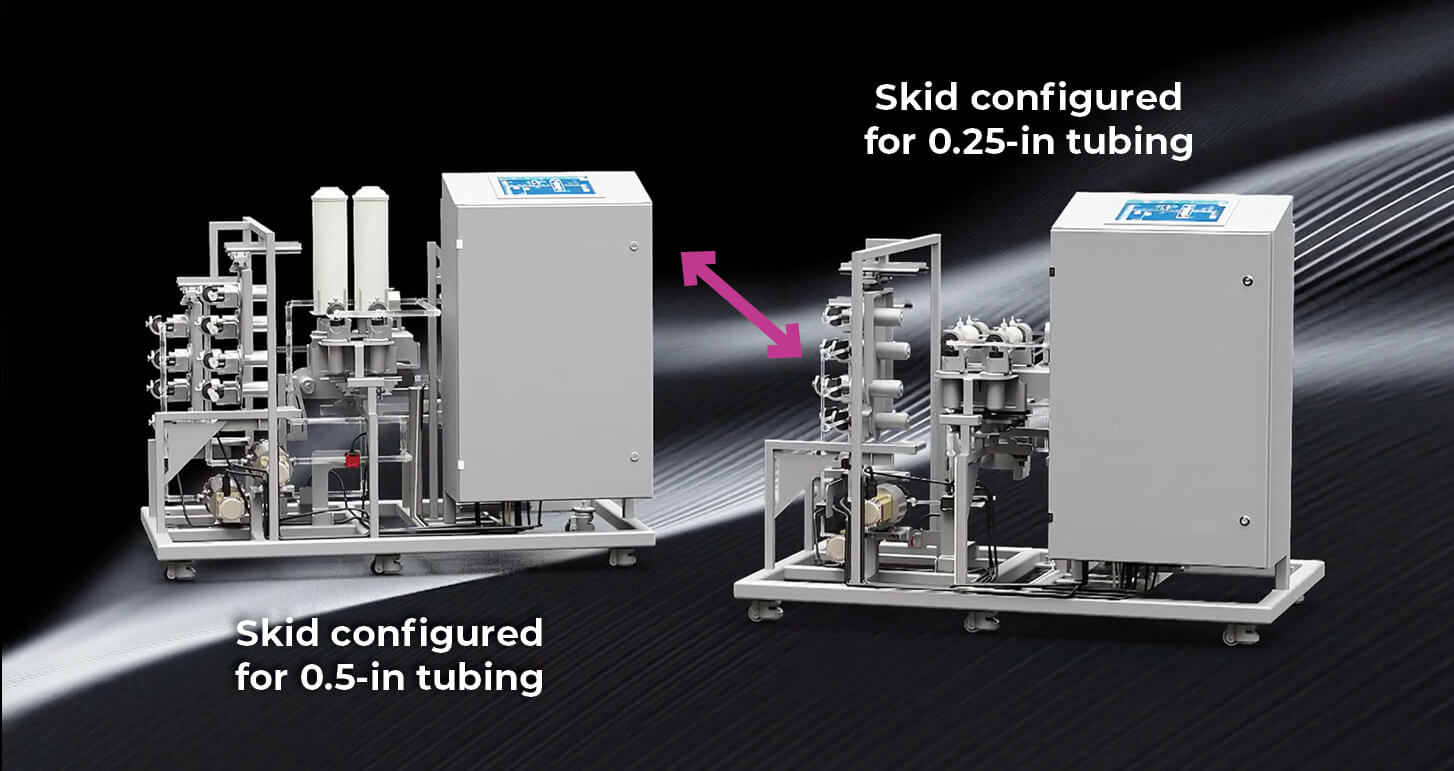

Introducing the 2-in-1 Scalable Single-use Chromatography System

Easily configure the same skid for 0.25 and 0.50 inch flow path assemblies.

Want to talk to an Agilitech Solutions Expert about the new Scalable Single-use Chromatography System?

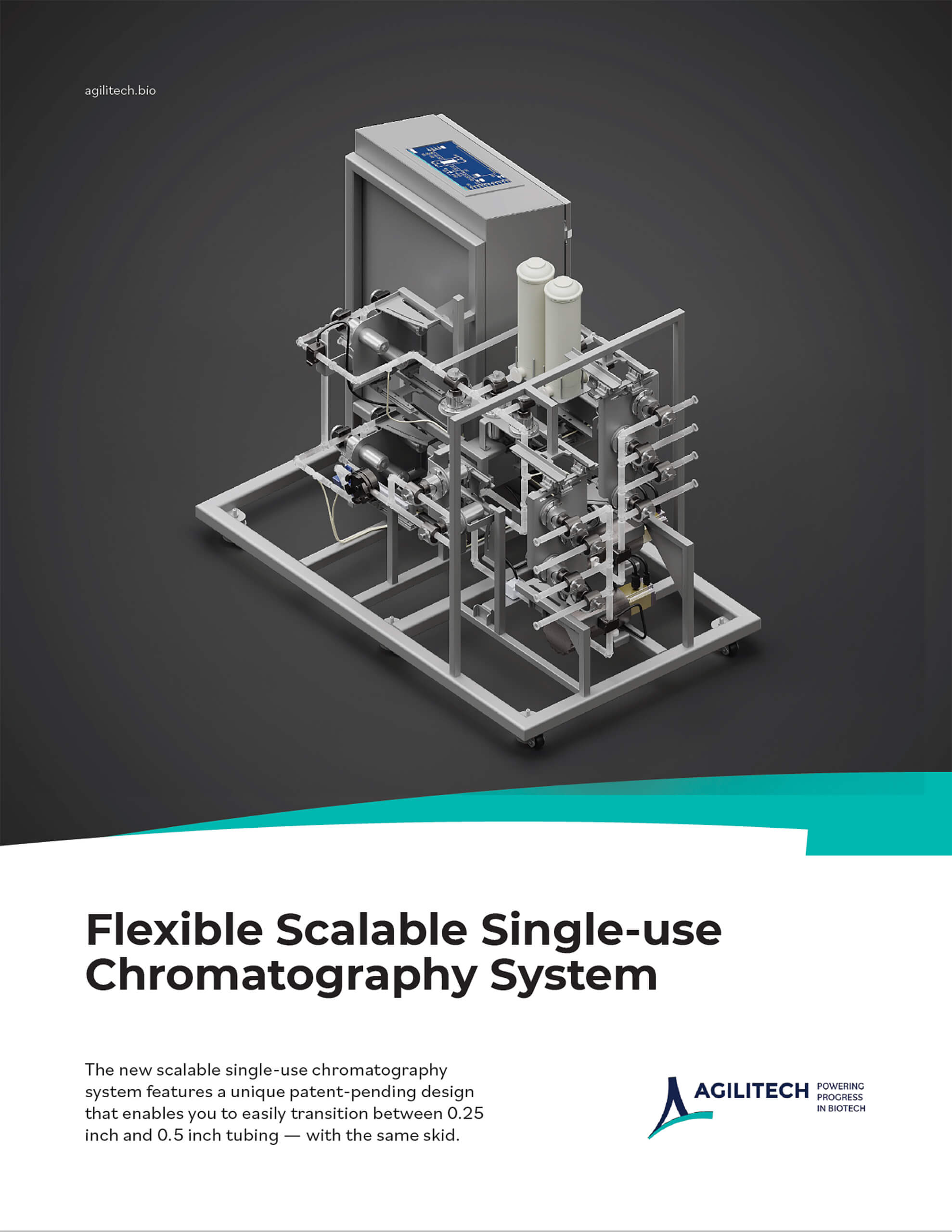

Future proof your bioprocess with the flexible Agilitech 2-in-1 Scalable Single-use Chromatography System

Configure the same skid for both 0.25-inch and 0.50-inch tubing assemblies—flow rate ranges up to 3 LPM and 15 LPM.

Patent-pending design enables fast and easy scale up from 0.25-inch to 0.50-inch tubing - or scale down - with the same skid

Quickly transition from one size flow kit assembly to another in one day

Brand-agnostic filters, columns, and other components enables the use of best-in-class parts for every aspect of the skid

Controls based on ISA-88 batch-compliant structure—manual to fully automated control with your preferred platform

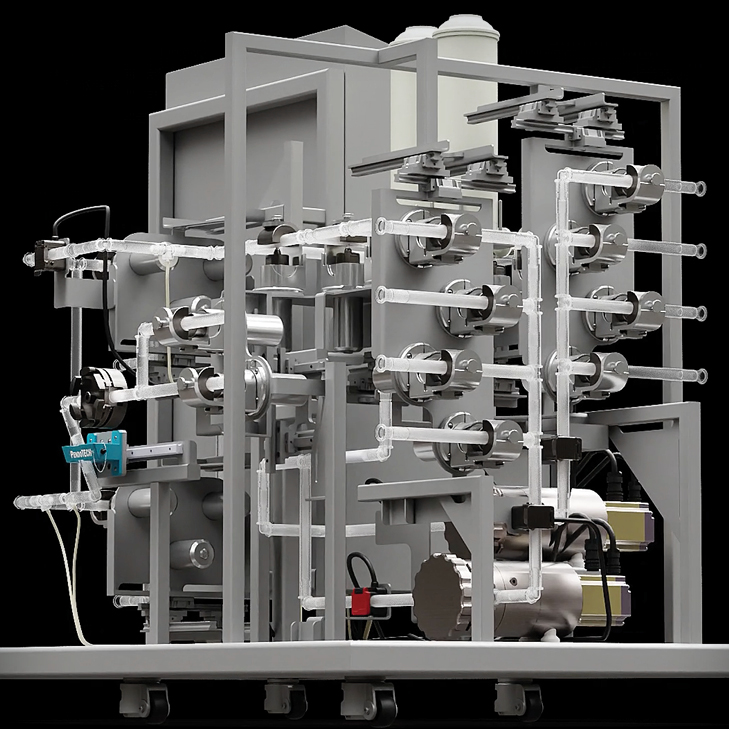

Flexible system design with configurable flow path to meet your precise requirements

Dual inlet headers with dedicated flow sensors – deliver accurate control throughout inline dilution and gradient steps

Outlet back pressure control valve—enables offline column pressure simulation to stabilize pumps and smooth transition to inline columns

Scaling your bioprocess – up or down – just got faster, easier, and more cost effective

At Agilitech, we’re committed to the development of innovative and flexible bioprocess solutions that empower our customers to achieve their goals. The new 2-in-1 scalable chromatography system, which features a patent-pending design, is the perfect example of this commitment.

A truly agile solution that delivers unprecedented time and cost savings

This flexible 2-skids-in-one solution enables you to easily scale up or down your process, or to handle different volumes within the same bioprocess. Within 24 hours, you should be ready to run your process at a scaled up or scaled down capacity, using exactly the same equipment, operations and interface that you’re used to.

With an Agilitech skid that scales, there’s no delay while you procure, configure, and qualify a new skid for the next stage of your process, and there’s no need to learn an entirely new platform and re-train operators. On top of that, there’s the significant cost savings by eliminating the need to buy a second skid.

The scalable chromatography skid can be configured and optimized for both 0.25-inch and 0.50-inch tubing by simply switching out the relevant components and tubing set. The same skid is optimized for two flow rate ranges—up to 3 LPM and 15 LPM.

When it comes to scaling up or scaling down your process, all of the components that you need to switch out are provided in your adaptor kit.

To change parameters when scaling up or down, simply select the right size from the control panel drop-down menu. The specifications for each scale are pre-programmed.

Agilitech chromatography systems integrate customizable single-use tubings sets of the highest quality manufactured by Entergris.

Want to talk to an Agilitech Solutions Expert about the new Scalable Single-use Chromatography System?

All of the benefits of our standard chromatography systems

Maximum flexibility

- Configured to meet your unique needs—whether it’s removing inlets/outlets, changing filters, etc., we can handle any combination of features/functions

- Column- and resin-agnostic—allows you to choose your preferred brand of columns/filters

- Flexible control: run manually, load individual steps (Prime, Wash, Load, Elution, etc.) or run a fully automated sequence

- Run process in upflow or downflow

- Transition from flow control to pressure control, if needed (in case of filter fouling)

- Run, bind and elute, or flow through process steps

- Add multiple column connections for serial operation, if needed

Controls based on ISA-88 batch-compliant

structure for manual to fully automated control

- Easy operation via user friendly control panel

- Can be delivered with your preferred automation and control platform: DeltaV, Rockwell Automation, Inductive Automation Ignition Software, Wonderware, or other platform

Single-use technology for a safe and sterile process

- Fully sterilized, single-use tubing set, complete with integrated sensors, minimizes risk of contamination

- Sterile-to-sterile connections for inlets/outlets reduce contamination risks

- Uses only the highest quality components, delivering USP <88> Class VI certified single-piece tubing sets that ensure sterility throughout use

Configurations

C250 Configuration

Tubing ID:

0.25 in

Flow Rates:

16–3000 mL/min

Flow Sensor

Performance:

0–8 LPM (± 3%)

C500 Configuration

Tubing ID:

0.50 in

Flow Rates:

0.167-15 LPM

Flow Sensor

Performance:

0–20 LPM (± 3%)

Technical Specifications

| Attribute | Specification |

|---|---|

| Pressure | 0-60 psi/4 bar |

| Operating Temperature Range | 2–50°C |

| Humidity (non-condensing) | 10–90% |

| Utility Required, Skid Power* | 110-120 VAC |

| Wetted Materials | USP <88> Class VI and animal free |

| Inlets | 8 (4 ea inlet header) |

| Outlets | 2 |

| Flow Accuracy | ±3% |

| Pressure Sensor Performance | 0–6 psi (± 2%) 6–30 psi (± 3%) 30–60 psi (± 5%) |

*Compressed air (oil free) @ 80 psi/5.5 bar

Specifications represent standard Agilitech models and may change when configured or customized for specific customer applications. Specifications subject to change without notice.

Literature

2-in-1 Scalable Single-use Chromatography System

(1.3 MB)

Service and support to fit your exact needs

All Agilitech single-use technologies are built to the highest standards and delivered with the documentation you need:

- Standard Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) documentation provided upon delivery; we can also use your specific documentation, if preferred

- Installation Qualification (IQ) and Operational Qualification (OQ) testing and documentation available for use in cGMP production

If needed, we will partner with you to develop Performance Qualification (PQ) testing; supplemental documents such as Qualification Project Plan (QPP), Criticality Assessment and Risk Assessment can also be provided.

All Agilitech single-use chromatography systems are delivered with a recommended preventative maintenance plan and spare parts list. We also provide maintenance service to ensure pumps, transmitters and all other components function within specification.